NASA's Marshall Space Flight Center: A hub for historic and modern-day rocket power

Wernher von Braun's crew built Saturn rockets here. Skylab, Hubble and Chandra all had roots here. Now, Marshall Space Flight Center tests rocket bodies for Artemis and engines for Blue Origin.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

NASA's George C. Marshall Space Flight Center has more than six decades of history designing, building and testing a storied series of rockets, rocket engines and instruments to fly in space. The center’s accomplishments include the Redstone rocket used to launch Project Mercury, the Saturn rockets for the Apollo program, the Skylab space station, and the Hubble Space Telescope.

Marshall is located on the grounds of the U.S. Army Redstone Arsenal in Huntsville, a city in northern Alabama about 145 miles (233 kilometers) northwest of Atlanta, Georgia. The NASA Center employs nearly 6,000 people, according to its official NASA website. Marshall also manages NASA's Michoud Assembly Facility near New Orleans, where giant rocket stages can be built and loaded onto barges for transportation to launch facilities at Kennedy Space Center in Florida.

Now, the Marshall Center is working on the Space Launch System (SLS) for the Artemis project that will land astronauts on the moon, as well as hosting private spaceflight company Blue Origin.

The original von Braun team

The Center's original core of rocketry talent was a team of about 125 Nazi engineers, led by Wernher von Braun, who had surrendered to the U.S. Army at the end of World War II. The group had been housed for a few years at Fort Bliss, Texas, where they supervised test firings of captured German V-2 rockets at nearby White Sands Proving Ground. In 1950 the team was moved to the grounds of Redstone Arsenal, an ammunition factory and test facility outside Huntsville, where they began work as the Army Ordnance Guided Missile Center, part of the Army Ballistic Missile Agency.

The German team, augmented by American military and civilian personnel, developed two new missiles: Redstone and Jupiter. Although they were conceived as weapons, both later became famous for civilian missions. A Jupiter rocket launched Explorer I, the first U.S. satellite, into orbit on Jan. 31, 1958, and Redstone rockets boosted the Mercury capsules flown by astronauts Alan Shepard and Gus Grissom in 1961.

Meanwhile, the von Braun team was thinking bigger, clustering elements of the Jupiter and Redstone rockets to make a series of giant multi-engine boosters. The product of that ambition, the first Saturn I rocket, would eventually fly in 1961.

When the National Aeronautics and Space Administration (NASA) was established at the direction of President Dwight Eisenhower in 1958, officials in both the Defense Department and NASA concluded that the Saturn rockets would be more useful for space exploration than for military missions. As a result, the von Braun team was transferred from the Army to NASA.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

As historians Andrew J. Dunar and Stephen P. Waring recount in "Power to Explore: A History of the Marshall Space Flight Center 1960-1990," (NASA History Office, 1999), von Braun believed in "dirty hands." Engineers, von Braun insisted, should have practical knowledge and should work closely with builders. This was especially true in the new field of rocketry, where so much was unknown and designs had to be worked out by experiment. Under his supervision, the Huntsville facility was laid out like a factory to keep design, manufacturing and testing in close proximity.

President Eisenhower dedicated the Huntsville rocket facility as the George C. Marshall Space Flight Center on Sept. 8, 1960. The facility was named for Marshall, an Army General who had served as Army Chief of Staff and as Secretary of State, and who had received a Nobel Peace Prize in 1953 "for proposing and supervising the plan for the economic recovery of Europe" after World War II.

Saturn rockets for Apollo

NASA officials were thinking about possible flights to the moon (and the giant rockets such missions would require) while Dwight Eisenhower was still president, as historian Roger Bilstein reports in his history of the Saturn program, "Stages to Saturn: A Technological History of the Apollo/Saturn Launch Vehicles" (NASA History Office, 1996). With President John F. Kennedy's 1961 declaration of the moon as a national goal, the Saturn rocket family — and therefore the Marshall Center — were given a clear mission: to provide power for the lunar voyage.

The Marshall Center took over management of the former Michoud Ordnance Plant near New Orleans, converting it into a factory that could build a Saturn stage and load it onto a barge for transportation to a launch site. The center already operated one such site in Cape Canaveral, Florida, which would eventually become the Kennedy Space Center.

Marshall Center teams completed the following tasks for the Apollo program:

- Built massive test stands large enough to hold an entire Saturn rocket stage on the ground while its engines were test-fired.

- Built a dynamic test stand large enough to hold an entire Apollo-Saturn V rocket and subject it to vibration and stresses like those expected during a launch. According to Dunar and Waring’s history, this stand, over 400 feet (122 meters) high, was the tallest structure in north Alabama at the time.

- Selected metals and invented new methods of welding to make the Saturn’s giant propellant tanks.

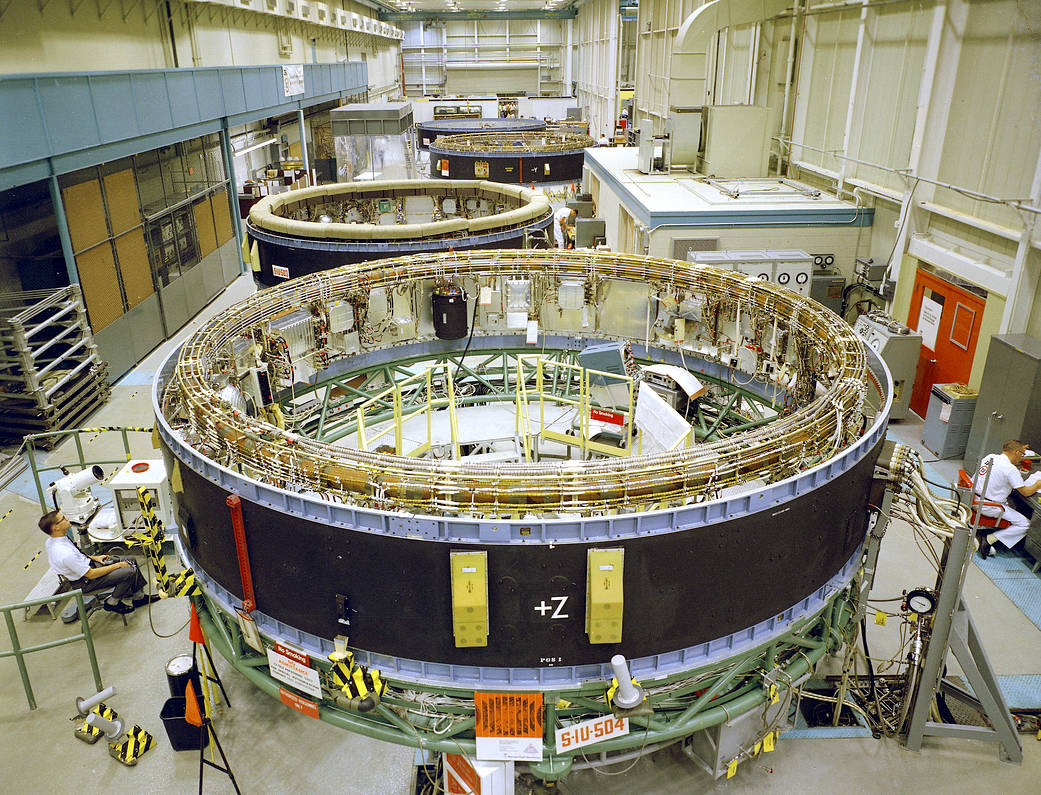

- Supervised IBM in building the Instrument Unit, a ring of computers at the top of the Saturn V third stage that could control and steer the vehicle independently of the Apollo spacecraft.

Once all the Saturn rockets needed for Apollo were finished or under construction, the Center got the job of providing the Lunar Roving Vehicle, an electric car that folded to fit in a spare compartment of the Apollo Lunar Module. Astronauts drove LRVs on the Moon as part of the Apollo 15, 16 and 17 missions.

Looking beyond Apollo, Marshall engineers conceived the idea of using an empty Saturn V third stage as a space station. That station, Skylab, was launched in 1973 atop the last Saturn V rocket ever to fly. Skylab hosted three crews of astronauts, each launched on a Saturn IB rocket. Skylab also featured another Marshall creation, the Apollo Telescope Mount, which precisely pointed a set of eight telescopes to observe the Sun.

The Marshall Center managed dozens of other science experiments using the Skylab microgravity environment, covering metallurgy, fluid dynamics, crystal growth and other sciences.

One last Saturn IB carried a crew into Earth orbit in 1975 to perform the first link-up between American and Soviet spacecraft in the Apollo-Soyuz Test Project.

From rockets to research

Diversifying beyond rocket propulsion post-Apollo, the Marshall Center took on new scientific projects, including:

- The first Laser Geodynamic Satellite (LAGEOS), launched in 1976. LAGEOS is a beach-ball-sized sphere of aluminum and brass covered with 426 retroreflectors that function as mirrors. The satellite reflected laser beams back to Earth to provide high-precision measurements of Earth’s continental drift.

- Gravity Probe-A launched from NASA's Wallops Island facility in Virginia in 1976. This suborbital space probe carried an atomic clock to a height of 6200 miles (9978 km). Comparing the flying clock to an identical one on the ground enabled physicists to test predictions about the effect of gravity on time in Einstein's theory of general relativity. Gravity Probe-B, launched into Earth orbit in 2004, used high-precision gyroscopes to test Einstein's predictions about spacetime near massive rotating bodies.

- A series of satellites called the High Energy Astronomical Observatories (HEAOs). HEAO-A, launched in 1977, spent 16 months surveying the sky for distant sources of X-rays such as pulsars, quasars and black holes. HEAO-B, also known as the Einstein Observatory, took the first astronomical images in X-rays in 1978, discovering that Jupiter and Earth emit X-rays. HEAO-C measured X-rays, gamma rays and cosmic ray particles during its 1979-81 mission.

To test HEAO-B, Marshall engineers built a facility featuring a guide tube 1,700 feet (518 meters) long that can send a beam of X-rays into a vacuum chamber 20 feet (6 m) in diameter and 60 feet (18.3 m) long. A telescope or spacecraft designed to observe X-rays from space can be placed in the chamber so that its focusing and measuring capabilities can be tested, using the X-ray beam as simulated starlight.

According to a NASA Fact Sheet, the system, now called the X-Ray and Cryogenic Facility (XRCF), was upgraded over the years to test the Chandra X-Ray Observatory, several meteorological satellites, the X-ray telescope on the Japanese Hinode satellite, and most recently the X-ray telescopes for NASA's Imaging X-ray Polarimetry Explorer (IXPE) satellite. The test chamber can be cooled to minus 414 degrees Fahrenheit (minus 248 Celsius), and was also used to test the mirrors for the James Webb Space Telescope, which are designed to function at extremely cold temperatures.

Space shuttle and ISS equipment

During the space shuttle era, Marshall teams supervised several private companies in making parts for the new spacecraft. Rocket manufacturing company Rocketdyne was responsible for the Space Shuttle Main Engines (SSMEs); chemical corporation Thiokol created the Solid Rocket Boosters (SRBs); and materials supplier Martin Marietta worked on the shuttle’s external tank, which was assembled at Michoud.

Marshall crews also managed the development of Spacelab, a pressurized module to host scientist-astronauts and their experiments on space shuttle flights, in a collaboration with European partners. Spacelab components flew on 36 Shuttle flights. As the program matured, the Marshall Center opened a Spacelab Mission Operations Control facility in Huntsville, where scientists could monitor experiments and communicate directly with astronauts conducting the experiments.

Marshall was NASA's lead center for designing and building the Hubble Space Telescope, which was launched from the space shuttle Discovery in 1990, as well as the Chandra X-Ray Observatory, which launched into Earth orbit from space shuttle Columbia in 1999. Both telescopes were still in operation as of early 2021.

As part of ongoing International Space Station operations, Marshall hosts the Payload Operations Integration Center, a control room that according to NASA has been staffed 24 hours a day, 365 days a year since 2001. Here, engineers and scientists manage the schedules and communications for science experiments aboard the Station.

The Marshall Center was responsible for design and testing of the Ares rockets, which would have launched cargo and crew vehicles as part of the Constellation program, an early-2000s project to connect the completion of the International Space Station to human missions to the moon and Mars.

Artemis at Marshall

The previous Constellation program has been superseded by the Artemis project, which aims to return astronauts to the moon using a new heavy-lift rocket, the Space Launch System (SLS).

According to a NASA fact sheet, the Marshall Center hosts two new static test stands, huge concrete and steel structures that can hold versions of entire SLS stages on the ground, pulling, crushing and contorting the structures to see how much stress they can take before they break. Marshall engineers are also developing the software that will steer SLS.

The Marshall Center, as manager of the Michoud Assembly Facility, hosts several private companies working on portions of the Artemis program. Staff from Boeing are working to build the SLS Core Stage and Exploration Upper Stage (EUS), for example, and according to NASA, a Teledyne Brown Engineering crew is building the launch vehicle stage adapter that will connect SLS's core stage to the upper part of the rocket. Meanwhile, a Lockheed Martin group is welding the primary structure of the Orion spacecraft that will carry astronauts atop the SLS, according to a NASA press release.

Tests of the RS-25 engines for the SLS Core Stage are being conducted at a nearby NASA facility, the Stennis Space Center, on the Mississippi Gulf Coast near New Orleans.

Now at Marshall

Other current work at Marshall includes:

- Inventing methods to make rocket engines by 3-D printing using lasers and metal powder. Some 3-D printed engine components, as described in this NASA press release, have already survived hot-fire tests.

- Solar Cruiser, a solar sail nearly 18,000 square feet (1672 square m), to be launched in 2025 to demonstrate the use of solar radiation for propulsion, according to a NASA announcement.

- SERVIR, a project that, according to updates from Marshall, will translate NASA satellite data into useful information about land use, agriculture, weather, climate, water and disasters, intended to help more than 45 developing nations.

- Adapting a vibration-suppressing device originally developed for the Ares rocket into a system to stabilize offshore wind turbines, as described in this NASA publication.

In 2019, Blue Origin, the private spaceflight company headed by Jeff Bezos, signed an agreement with NASA to refurbish and use Marshall’s Test Stand 4670, built in 1965 to test Saturn rockets. Blue Origin will use the stand to test engines the company will make at a new factory in Huntsville, a Blue Origin press release stated. According to a story in Made in Alabama, website of the Alabama Department of Commerce, the Blue Origin factory plan was originally code named “Project Rumble,” referring to the sound of rocket engines being tested at Marshall.

Additional resources

- What was it like to work for Wernher von Braun at Marshall? Read a sample of his management memos from the 1960s.

- Watch a Space Launch System propellant tank being intentionally stressed on a Marshall test stand until it breaks.

- Explore the Marshall Center with 360-degree video tours.

Steve is a former contributor to Space.com in the coverage areas of stars, exoplanets, and constellations. He's an author, podcaster, and retired Planetarium Director at Rochester Museum & Science Center where he was employed for 28 years and responsible for content and scheduling of the venue's Planetarium astronomy shows. Other duties included adapting still and moving images, music and sound, narrating shows, and leading selection and scheduling of all film and laser shows. His book, Sky to Space: Astronomy Beyond the Basics with Comparisons, Ratios and Proportions was published in 2017.