'A completely new manufacturing frontier': Space Forge fires up 1st commercial semiconductor factory in space

Such experiments have previously only been conducted aboard the International Space Station.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Twice a month

Strange New Words

Space.com's Sci-Fi Reader's Club. Read a sci-fi short story every month and join a virtual community of fellow science fiction fans!

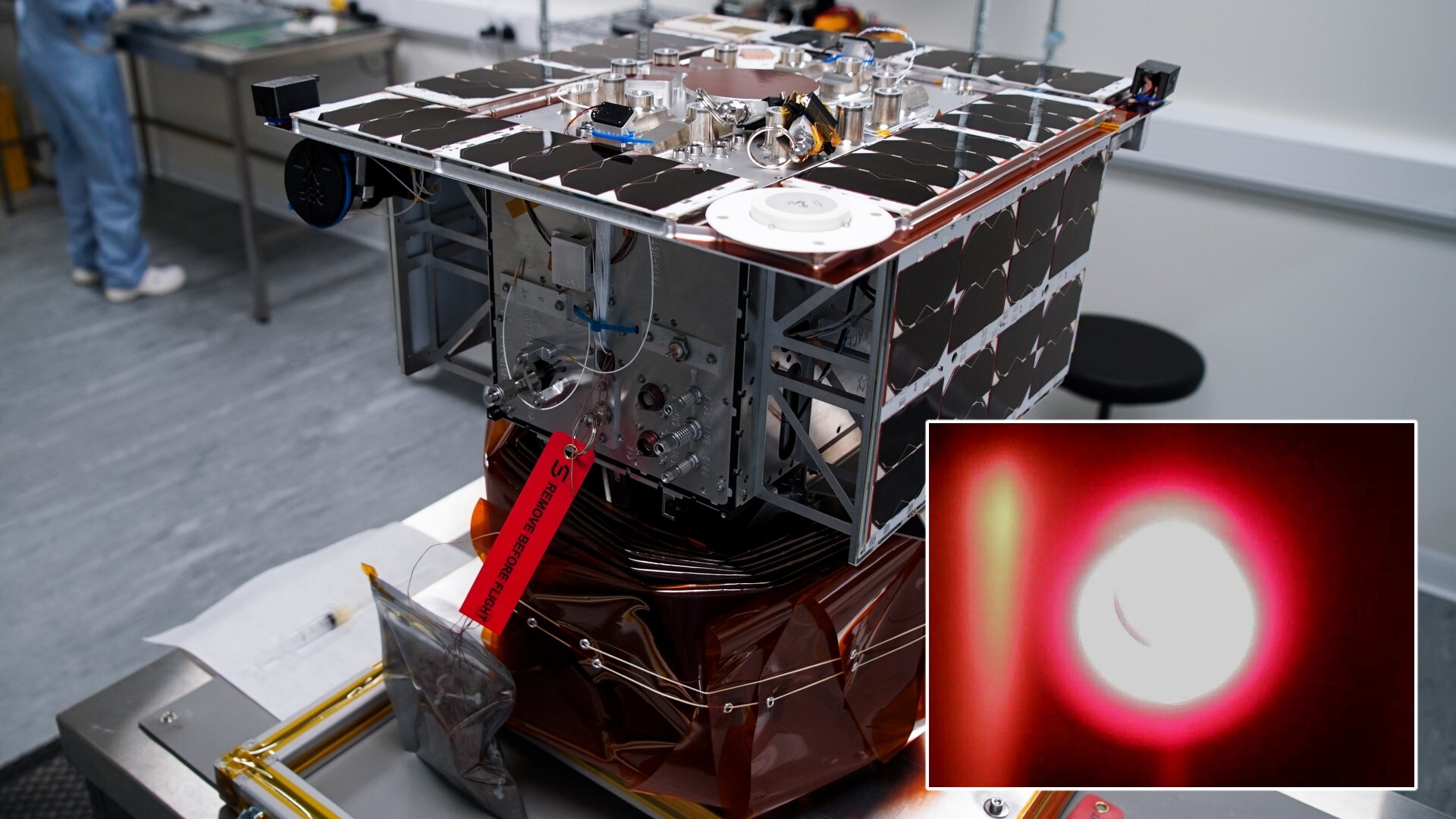

In-orbit manufacturing start-up Space Forge has produced its first plasma in orbit aboard the ForgeStar-1 satellite. It's a world first and a major step toward the company's vision of making novel semiconductors in space, which could revolutionize future electronic technologies.

UK-based Space Forge launched its pioneering ForgeStar-1 craft in June 2025 and has been bringing it to life since. In December 2025, the microwave oven-sized satellite fired up its miniature furnace for the first time and generated plasma — a stream of gas as hot as 1,832 degrees Fahrenheit (1,000 degrees Celsius). In future missions, such plasma will help SpaceForge forge super efficient, out-of-this-world materials in weightlessness.

"Generating plasma on orbit represents a fundamental shift, it proves that the essential environment for advanced crystal growth can be achieved on a dedicated, commercial satellite — opening the door to a completely new manufacturing frontier," Joshua Western, CEO and co-founder of Space Forge said in a statement.

SpaceForge, founded in 2018, plans to use a similar furnace on a future satellite to manufacture a batch of novel semiconductors directly in the weightless environment of space. Such experiments have previously only been conducted aboard the International Space Station.

"The plasma demonstration confirms that the extreme conditions needed for gas-phase crystal growth — a core building block of semiconductor production — can now be created and controlled on an autonomous platform in low Earth orbit," the company said in the statement. "The achievement establishes ForgeStar-1 as the first free-flying commercial semiconductor manufacturing tool ever operated in space."

Thanks to the absence of gravity, atoms in semiconductors grown in space align so accurately that the resulting material provides a superior performance to anything made on Earth. Space Forge estimates that the improved efficiency of these semiconductors could enable reductions in the energy use of electronic devices by up to 60 percent.

The semiconductors, based on rare materials such as gallium nitride, silicon carbide or diamond, could be used in future telecommunications systems, electronic devices and next-generation computers.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

The current ForgeStar-1 will only test the orbital factory equipment. The satellite will deorbit and burn up in the atmosphere later this year. Before its mission ends, the craft will run more experiments to analyze how the generated plasma behaves in microgravity and collect data to help the company's engineers fine-tune the future missions.

Space Forge raised a generous Series A funding round of £22.6 million ($30.5 million) last year that will allow the company to build the successor satellite ForgeStar-2, which will make the first batch of Space Forge's made-in-space semiconductors. The spacecraft will be fitted with a novel heat shield to survive the atmospheric return and deliver its precious cargo safely to Earth.

Tereza is a London-based science and technology journalist, aspiring fiction writer and amateur gymnast. She worked as a reporter at the Engineering and Technology magazine, freelanced for a range of publications including Live Science, Space.com, Professional Engineering, Via Satellite and Space News and served as a maternity cover science editor at the European Space Agency.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.