Airplane Wing Actively Morphs for More Agile, Efficient Flying

Even modern airplanes are a crude approximation of natural flight. The stiff wings and mechanical flaps and ailerons have nothing on birds that can flex, twist and flap their wings to adjust precisely to taking off, landing, flying fast or slow, turning, climbing or diving.

Now a collaboration between engineers at NASA and MIT has resulted in a shapeshifting wing that's as close as anyone has gotten to mimicking the natural agility of birds. The so-called Digital Morphing Wing could greatly improve an aircraft's fuel-efficiency, reduce its emissions and make it soar through the sky more smoothly and quietly than conventional planes.

Putting a dollar amount on that fuel efficiency is a little tricky. The standard approach in the airline industry has been to tweak current designs in order to squeeze out more miles per gallon. Take, for example, the curved wingtips that started showing up on commercial jets in the last decade or so. Those winglets, as they're called, reduce drag and can improve a plane's fuel efficiency by 5 or 6 percent, depending on the aircraft.

But some engineers want to do away these kinds of incremental changes altogether and design an entirely new aircraft from scratch. Some studies show that a completely redesigned airplane could see a 70 percent reduction in fuel use.

"The morphing wing technology that we're working on can contribute significantly to this and result in significant energy-use savings," NASA's Kenneth Cheung, co-lead on the project, told Seeker.

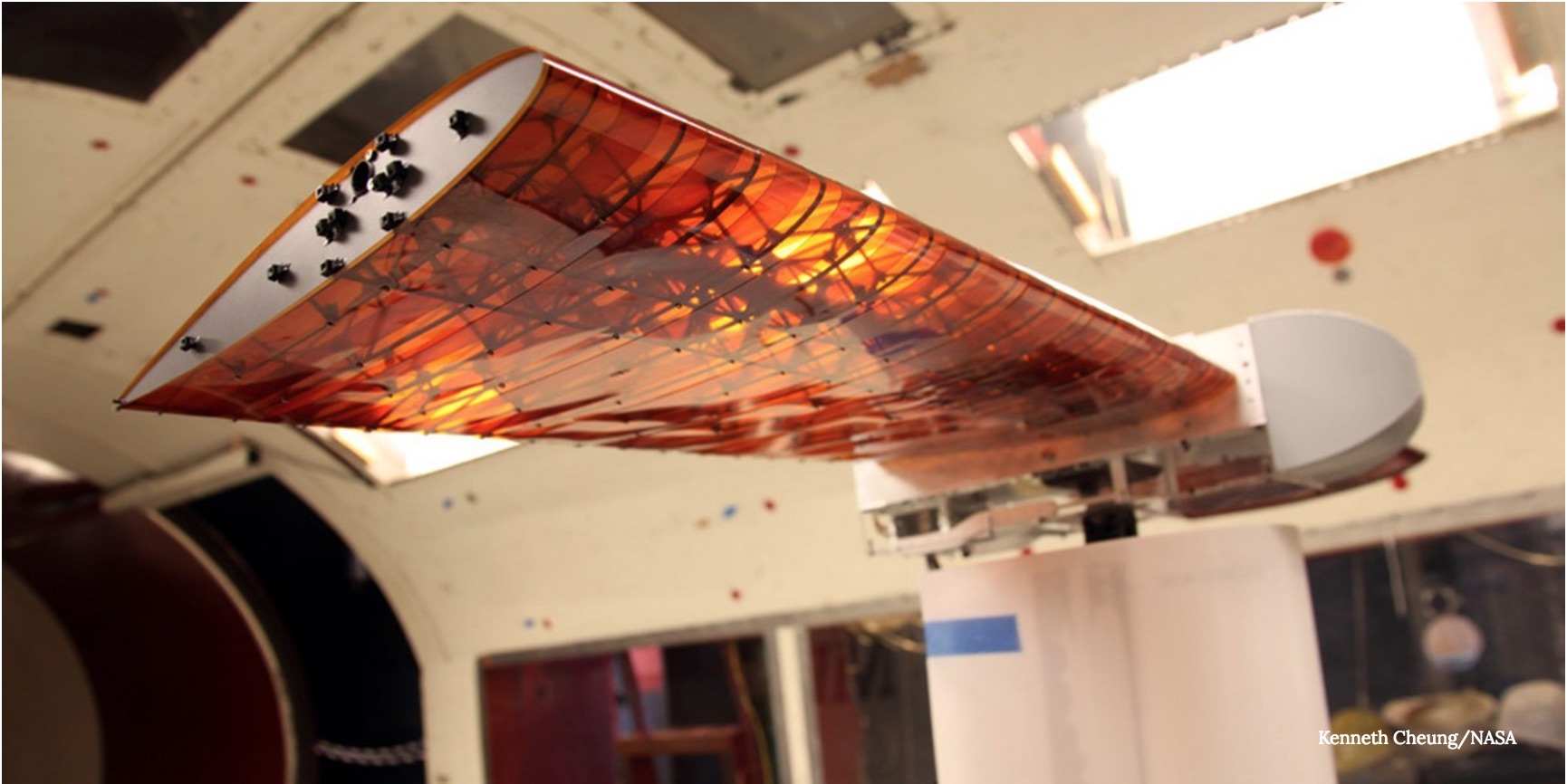

Indeed, the morphing wing represents a complete design overhaul. Instead of fabricating the wing from sheets of metal riveted together, the engineers started from the inside. They constructed small components that resembled multi-sided spheres or cubes — a kind of Tinker Toy geometry. In tests, the scientists found that the lattice shapes, made from carbon fiber, were strong and stiff but at the same time, lightweight, and had the ability to flex.

They are also modular, which means that individual subunits can be linked together to form a much larger object of any size or shape.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

In this case, the scientists linked the subunits together to form a wing about five feet across. Instead of covering it in metal, they covered it in a thin skin of lightweight polymide film, which is used in spacecraft and in solar panels.

It took just two small motors to twist the entire wing. In a wind tunnel test at NASA's Langley Research Center in Virginia, the wing withstood the tunnel's maximum airflow capacity.

For the purposes of this study, the engineers assembled the lattice-like subunits by hand into the experimental wing. But the team already imagines a future where robots piece together the cells, Lego-style, into any shape needed. That could simplify the manufacturing process.

"The next step is a complete morphing aircraft," said Cheung.

The future may also include morphing machines that travel through water, as well as air.

"A great deal of our oceans are unexplored," Cheung said. "It's possible that this kind of manufacturing method could make very efficient swimming submersibles that are also relatively inexpensive to build and maintain."

Originally published on Seeker.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Tracy Staedter is a freelance science writer, editor, writing coach, and consultant with an eclectic career spanning over 20 years. She's has covered a range of science and technology stories from astrophysics to zero waste. She worked on staff for such online sites and publications as Space.com, LiveScience.com, Astronomy, Scientific American Explorations, MIT Technology Review, DNews, and Seeker. She also wrote the illustrated book, Rocks and Minerals (part of the Reader’s Digest Pathfinders series) and founded the Fresh Pond Writers workshop for fiction and creative nonfiction writers.