In photos: First look inside Orbex's Scotland rocket factory

The private space company Orbex recently released the first photos of its rocket factory in Scotland, offering a glimpse at where the commercial orbital rocket called Prime is being built.

Orbex is targeting small-satellite launches from an as-yet-unbuilt spaceport called Space Hub Sutherland. And in early 2020, the company signed up a new client, a company called TriSept, looking to launch a dedicated ride-share mission in 2022.

The Prime rocket will use the world's largest 3D-printed rocket engine, which is powered by biopropane, a clean-burning, renewable fuel source. Using biopropane will reduce carbon emissions by about 90%, compared with standard kerosene-based rocket fuels, according to Orbex.

In addition, Orbex said that it designed Prime rockets to leave no orbital debris; the rockets are also made out of lighter materials, which the company said will facilitate recovering and reusing the main stage. The company plans to launch Prime from northern Scotland as early as 2021.

Founded in 2015, Orbex built its headquarters in Forres, Scotland, where key elements of the launch vehicles are manufactured and tested. From there, the rockets will head to a launch site overseas or the proposed Scottish spaceport.

That spaceport, which will be called the Space Hub Sutherland, is still pending approval for construction. It would be built on the Moine Peninsula in the county of Sutherland, a few miles from Scotland's Atlantic coast. The facility would enable vertical rockets to launch small satellites into low-Earth polar and sun-synchronous orbits.

Orbex engineers inspected the company's newest rocket engine test site in the UK to ensure it will be ready for future propulsion tests. The company also plans to open a second test site in Denmark to allow full-stage static tests.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Orbex personnel will monitor tests at both sites from the company's new mission control center in Forres, Scotland. Here, flight controllers will be able to access data from the launch vehicle during liftoff and flight, providing complete remote command and control. Orbex will use the facility to monitor orbital rocket launches from Scotland and other sites.

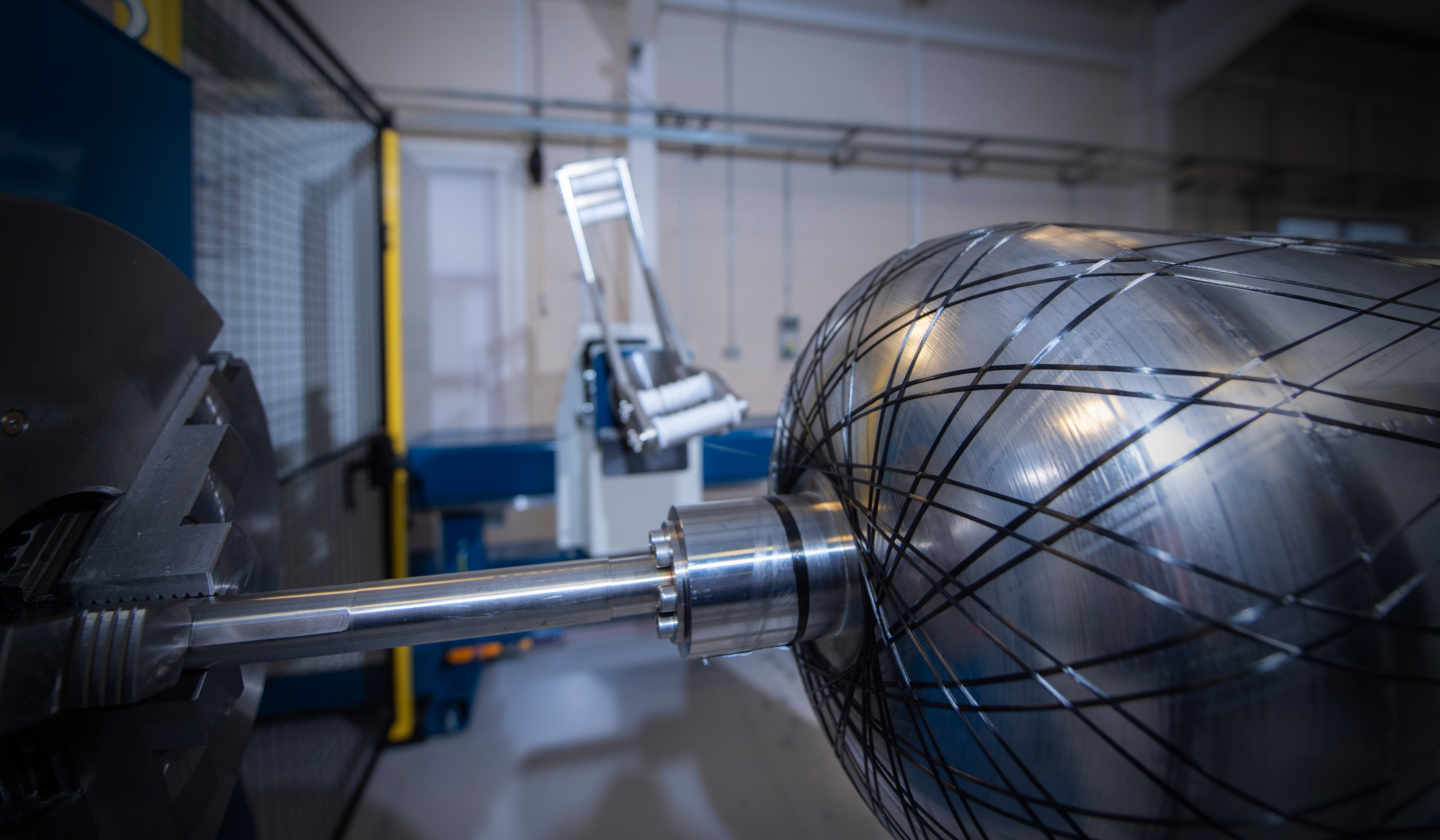

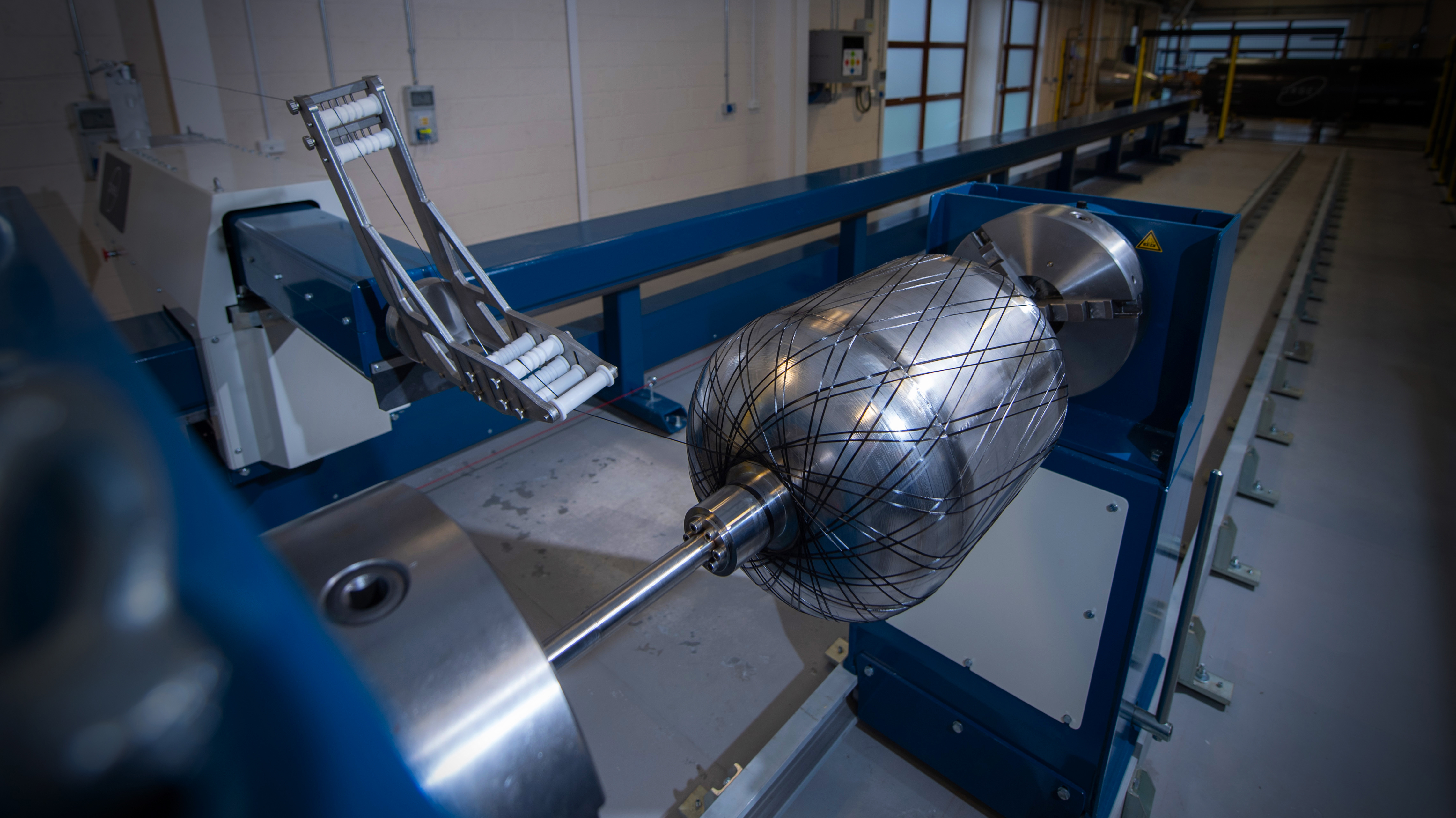

Orbex has also installed a carbon-fiber-winding machine at the rocket factory at its headquarters in Scotland. It is one of several new production systems installed at the facility and one of the largest high-speed carbon-fiber winding machines in Europe, according to the statement.

"This 18-meter-long machine automates the rapid weaving of intricate mixes of materials to build the main rocket structures," Orbex officials said in the statement, adding that it has taken several years to create the optimal blend of lightweight carbon-fiber and aluminum composites.

Using this carbon-fiber blend will make the Prime rocket up to 30% lighter than other rockets of its size and allow the rocket to accelerate from 0 to 830 mph (1,330 km/h) in just 60 seconds, Orbex said.

Orbex's carbon-fiber winding machine provides automated control of the fiber strands, also known as rovings, and allows Orbex to weave different materials together to build the main rocket structures.

"Numerous characteristics, from the basic material properties to the angle of the stands, all combine to ensure essential structures can tolerate large pressures — in some cases up to 500 times atmospheric pressure — as well as the intense dynamic loads of an orbital space launch vehicle," according to the statement from Orbex.

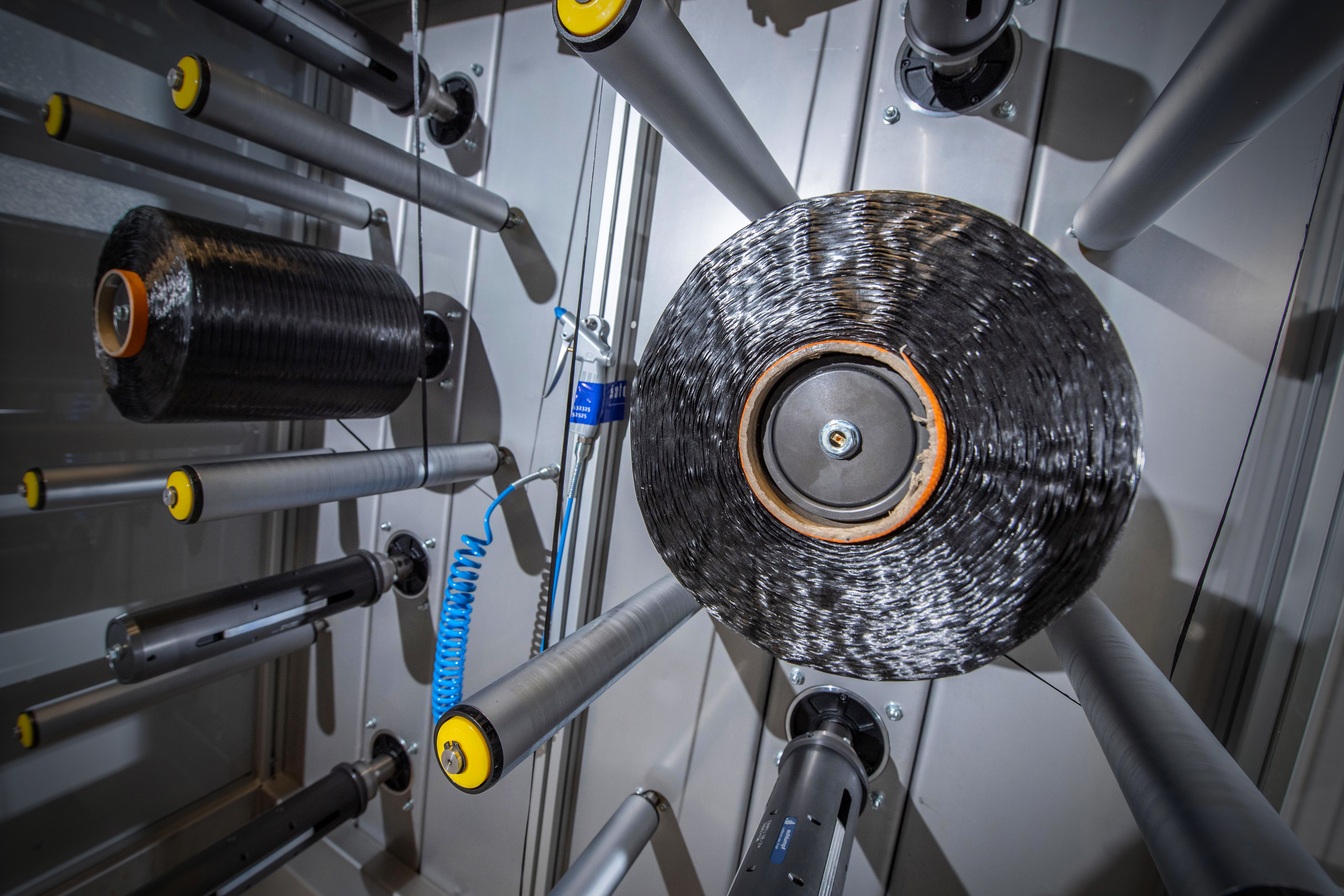

This photo shows a bobbin from which the fiber strands are woven. The blend of materials used in the carbon fiber for the construction of the Prime rocket was developed by Orbex over the last several years, according to the statement.

"This equipment allows engineers to have complete control over the design and pace of manufacture of all carbon fiber tanks, including the main stage tanks, which can be wound in a matter of hours," according to the statement from Orbex.

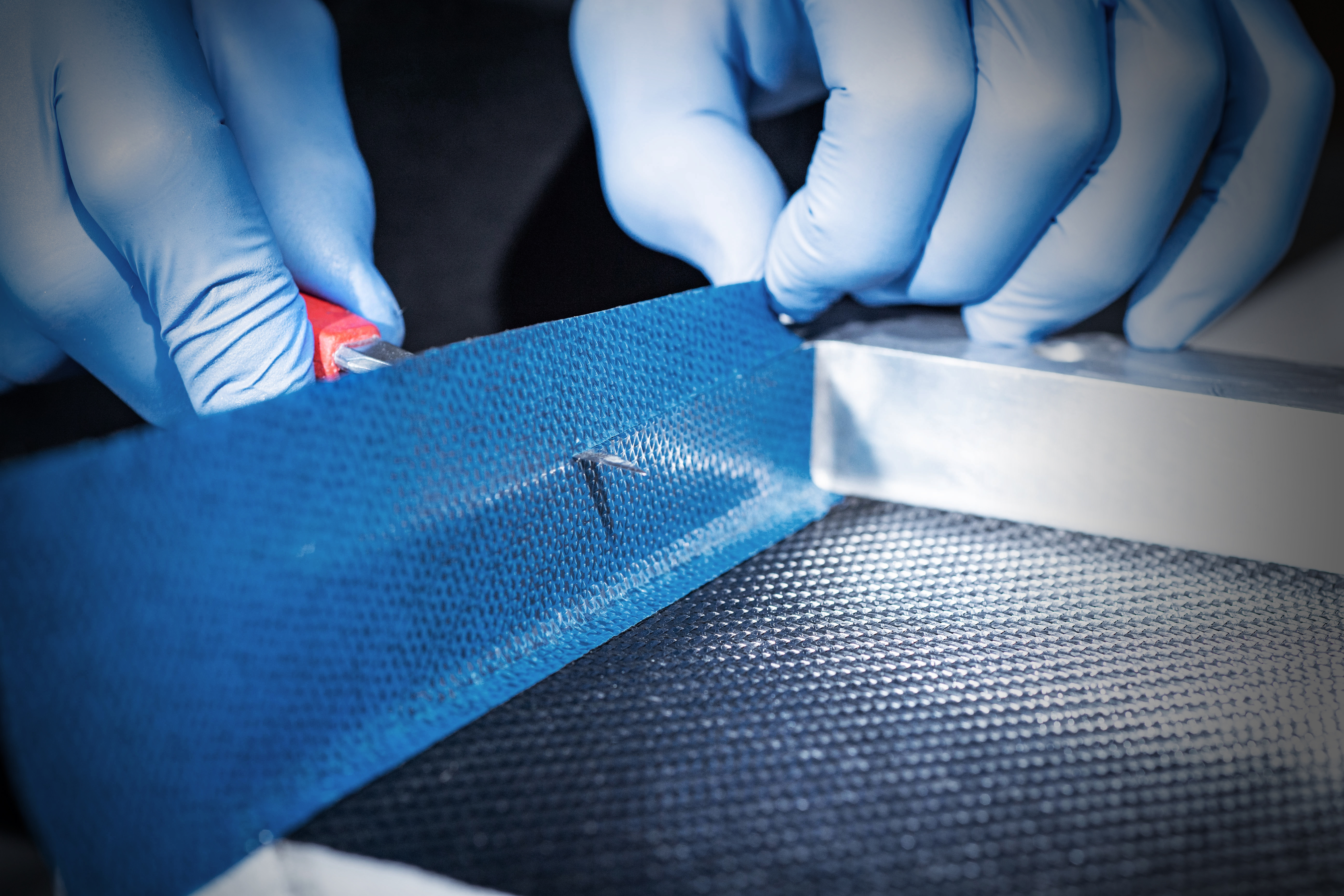

Engineers trim the carbon-fiber fabric before placing it in a component mold for the heating and curing process. The carbon fiber is pre-impregnated with a resin system to reinforce the fiber blend. This fabric is not only lighter than traditional aerospace materials, but also nearly twice as strong, according to Orbex.

Orbex has received funding from the UK Space Agency's Spaceflight Program to support the manufacture of this carbon-fiber technique. Orbex has also received support from the European Horizon 2020 SME Instrument program, which is part of the European Innovation Council and provides funding opportunities to small companies like Orbex.

In this photo, Orbex engineers are drilling the carbon-fiber composites, which are widely used in specialized, high-performance products like aircraft, race cars and spacecraft.

"We're creating rockets in a way that hasn't been done before," Chris Larmour, Orbex CEO, said in the statement. "The whole point of NewSpace — private enterprise getting involved in spaceflight — is to provide faster, better and cheaper access to space. Burning through hundreds of millions of dollars on robotic assembly lines or hundreds of staff to produce heavy, metal rockets is an antiquated approach."

At the same rocket factory, Orbex also recently installed a full-scale autoclave, which engineers use to "cure," or harden, the carbon-fiber structures under heat and pressure. The autoclave uses high temperatures and up to seven times the atmospheric pressure to bind the materials and strengthen the carbon fiber.

In this photo, an Orbex engineer verifies the temperature inside the autoclave to ensure a solid bond is established between the carbon fiber composites. The autoclave is used to cure all composite rocket parts, including the main-stage tanks.

"In just a few hours, these machines can process large composite rocket parts to create a strong and reliable structure that is ready for the extremes of space," according to the statement.

This photo offers an up-close view of a 3D-printed rocket engine. 3D-printing incorporates tiny design details and features that would otherwise require additional processing time. Using this technique, Orbex is able to create a complete rocket engine in just five days.

In addition, Orbex believes its 3D-printed rocket engine may be safer than conventional engines, as it is manufactured as a single piece without joints, seams or welds. That should make it better able to withstand extreme temperature and pressure fluctuations of spaceflight, according to Orbex.

Each Prime rocket requires six 3D-printed engines on the first stage and a seventh engine on the second stage. Weighing just 16.5 lbs. (7.5 kilograms), each of Orbex's 3D-printed rocket engines can lift 7,000 lbs. (3,200 kg) and requires only 8,800 lbs. (4,000 kg) of fuel per launch. Each Prime rocket is approximately 50 times more fuel-efficient than other small-satellite launch vehicles, which use up to 440,000 lbs. (200,000 kg) of fossil fuels.

In addition, Orbex has been testing the performance and reliability of biopropane-fueled engines, which use "clean" fuel supplies to reduce carbon emissions, compared with conventional hydrocarbon fuel-fired rockets, according to a statement.

High-performance turbo-pumps that spin at up to 25,000 rotations per minute feed fuel into the rocket engines. This photo shows the gearbox, which is part of a system that provides high-speed testing and rotor balancing of rocket engines, according to Orbex.

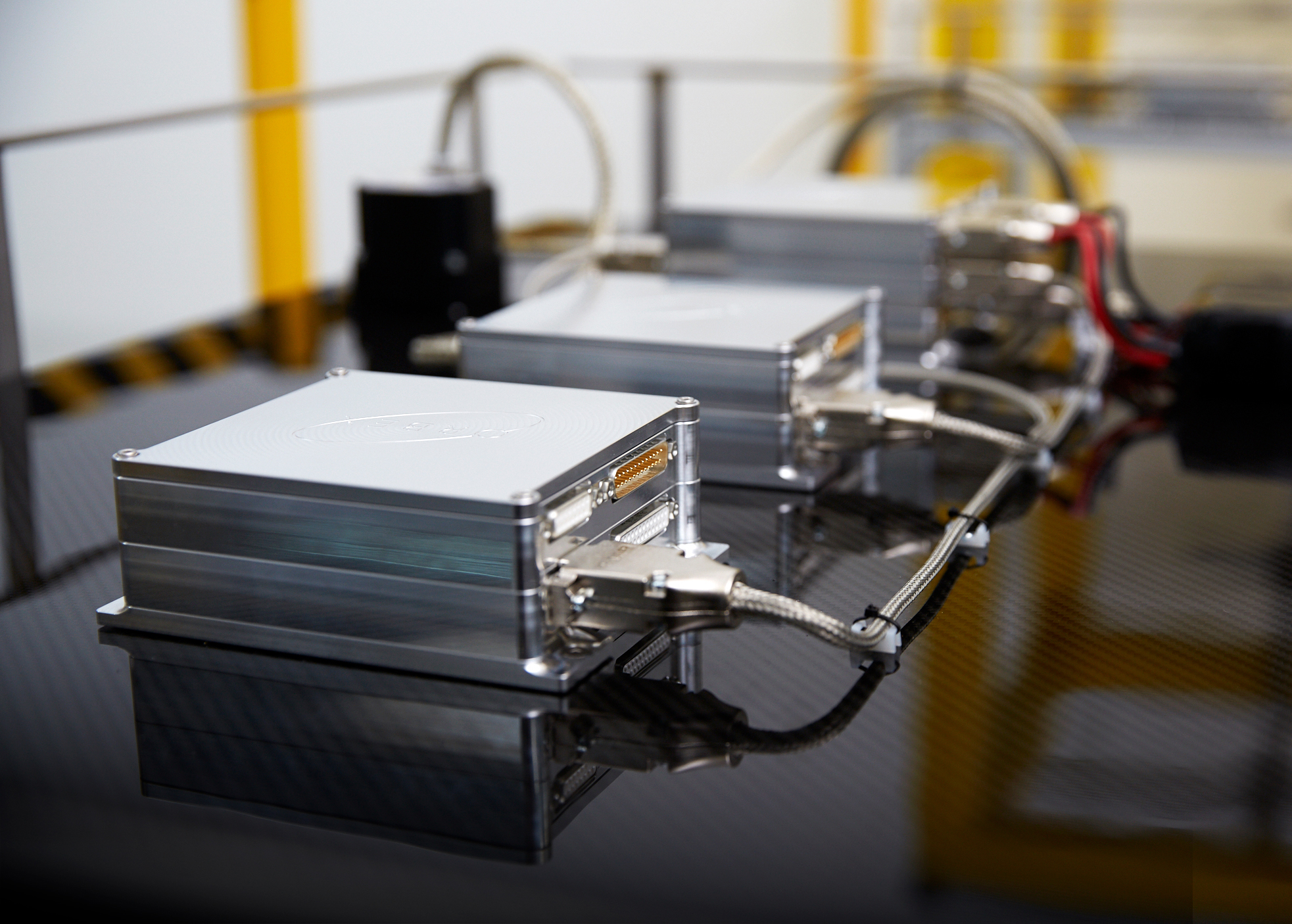

Orbex has also developed a full hardware system the company calls a "flat sat," which consists of flight computer and guidance sensors.

"Many satellites are now as small as a smartphone," Larmour said in the Orbex statement. "Our goal is to service this new market by making smaller, more efficient launch vehicles with a tiny [carbon dioxide] footprint and zero orbital debris."

He is also targeting scheduling to keep the reusable launch vehicles flying regularly. "We can only do that [by] re-thinking how we do it, rather than copying the past."

- Blue Origin's giant rocket facility is taking shape in Florida

- Space treasures in the Rockies: Inside Lockheed Martin spaceship factory

- SpaceX is building a 'Starship' rocket prototype in Florida, too

Follow Samantha Mathewson @Sam_Ashley13. Follow us on Twitter @Spacedotcom and on Facebook.

Samantha Mathewson joined Space.com as an intern in the summer of 2016. She received a B.A. in Journalism and Environmental Science at the University of New Haven, in Connecticut. Previously, her work has been published in Nature World News. When not writing or reading about science, Samantha enjoys traveling to new places and taking photos! You can follow her on Twitter @Sam_Ashley13.