Made In Space to Step Up Off-Earth Production of Valuable Optical Fiber

Off-Earth production of the valuable optical fiber ZBLAN will soon reach Phase 2, if all goes according to plan.

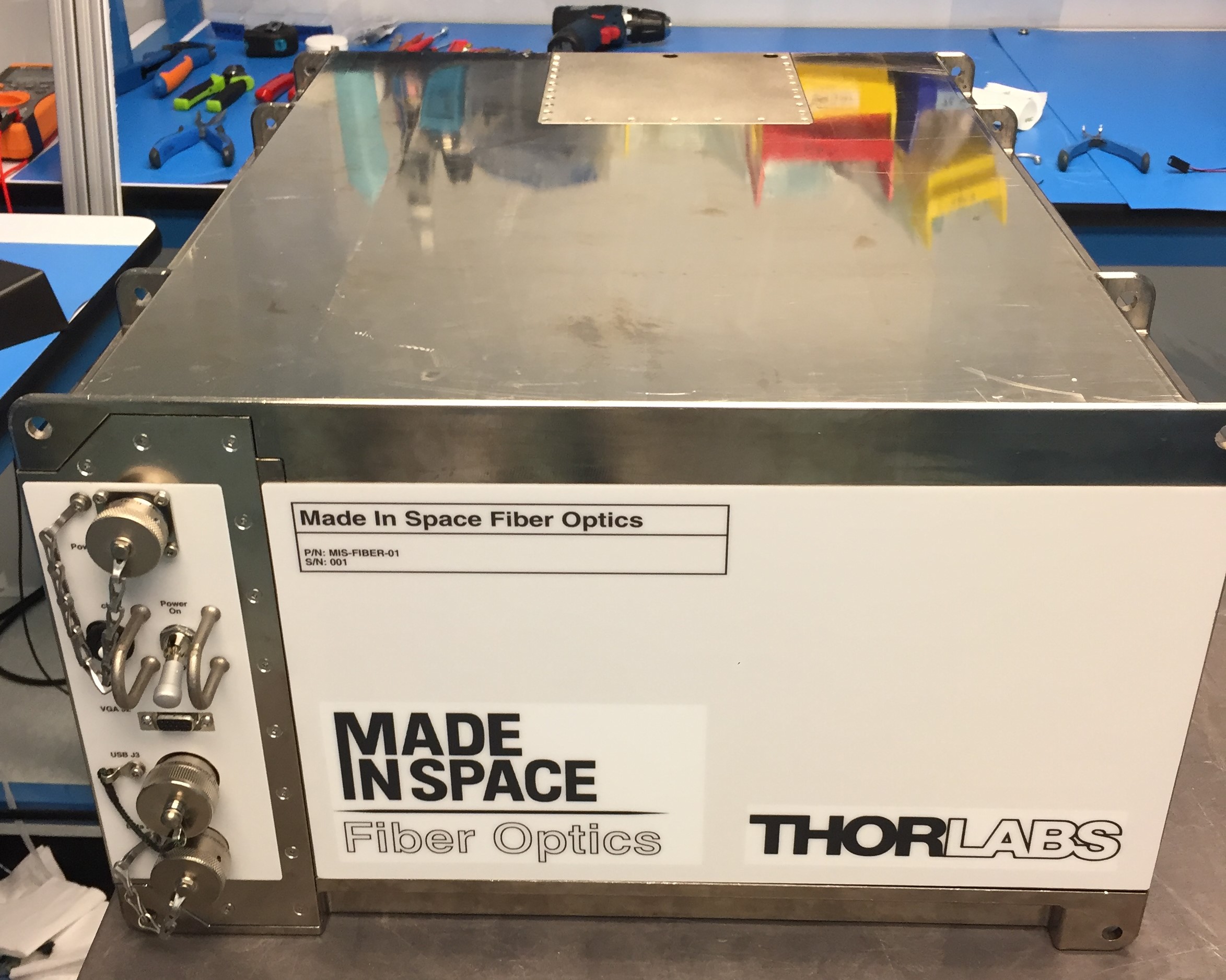

California-based company Made In Space has already produced ZBLAN in orbit on four separate occasions, using a microwave-size machine that traveled to and from the International Space Station (ISS) aboard SpaceX Dragon cargo capsules.

The results of these early tests were promising, Made In Space representatives said, so the company intends to ratchet things up.

Related: 3D Printing in Space: A Photo Gallery

"We're going to launch a slightly larger facility to the space station in about the next year or so to produce more material, both for additional study and for potential sale," Andrew Rush, Made In Space president and CEO, said late last month during a media event at NASA's Ames Research Center in Silicon Valley, which featured a visit by NASA Administrator Jim Bridenstine. (Made In Space has facilities on the Ames campus.)

"We have some good potential customers lined up already," Rush added.

One of Made In Space's main goals is to help establish a robust off-Earth economy, which, in turn, could enable humanity to extend its footprint out into the solar system. The company views ZBLAN production as an important early step in that direction.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

The material has the potential to be markedly superior to traditional silica-based optical fiber, but it's difficult to make on Earth because our planet's strong gravity induces imperfections in the ZBLAN crystal lattice, Made In Space representatives have said.

And ZBLAN is both lightweight and valuable, selling for about $100 per meter, Rush said. So it could be a good gateway product, demonstrating the commercial viability of off-Earth manufacturing and allowing Made In Space to turn a tidy profit at the same time.

But the company isn't putting all of its eggs in the ZBLAN basket. Made In Space has also launched two 3D printers to the ISS, one of which, the Additive Manufacturing Facility (AMF), is available for commercial use.

And another machine should be going up soon, before the second-generation ZBLAN facility launches: Made In Space aims to loft its Plastic Recycler to the ISS sometime this fall, Rush said. The Recycler will process waste plastic into feedstock filaments the AMF can use, demonstrating technology that could increase the efficiency and sustainability of exploration missions.

Then there's Archinaut, Made In Space's spacecraft-assembly technology. The system consists of a 3D printer and robotic manipulator arms, which together could repair and augment existing satellites as well as build entirely new structures on orbit.

NASA recently awarded Made In Space $73.7 million to give Archinaut its first orbital test. The Archinaut One demonstration mission will launch aboard a Rocket Lab Electron booster as early as 2022.

NASA thinks the return on that investment could end up being huge.

"If we can actually manufacture in space rather than manufacturing on Earth and launching everything, it can be an absolute game-changer that enables us as an agency to optimize what we're trying to achieve," Bridenstine said.

"We think about larger antennas, or larger [space telescope] apertures or the ability to print things in three dimensions in space and then robotically assemble those things — that has capabilities that are going to be absolutely game-changing for NASA but also really for our other partners in the U.S. government and commercial industry at the same time," he added.

- 'Archinaut' Spacecraft Could Build Huge Structures in Space (Videos)

- Satellite Quiz: How Well Do You Know What's Orbiting Earth?

- 3D Printing: 10 Ways It Could Transform Space Travel

Mike Wall's book about the search for alien life, "Out There" (Grand Central Publishing, 2018; illustrated by Karl Tate), is out now. Follow him on Twitter @michaeldwall. Follow us on Twitter @Spacedotcom or Facebook.

Michael Wall is a Senior Space Writer with Space.com and joined the team in 2010. He primarily covers exoplanets, spaceflight and military space, but has been known to dabble in the space art beat. His book about the search for alien life, "Out There," was published on Nov. 13, 2018. Before becoming a science writer, Michael worked as a herpetologist and wildlife biologist. He has a Ph.D. in evolutionary biology from the University of Sydney, Australia, a bachelor's degree from the University of Arizona, and a graduate certificate in science writing from the University of California, Santa Cruz. To find out what his latest project is, you can follow Michael on Twitter.