Made In Space's 'Archinaut' Could Build Big Power Systems for Small Satellites

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Twice a month

Strange New Words

Space.com's Sci-Fi Reader's Club. Read a sci-fi short story every month and join a virtual community of fellow science fiction fans!

Small satellites will soon pack an outsize power punch, if one company's plans come to fruition.

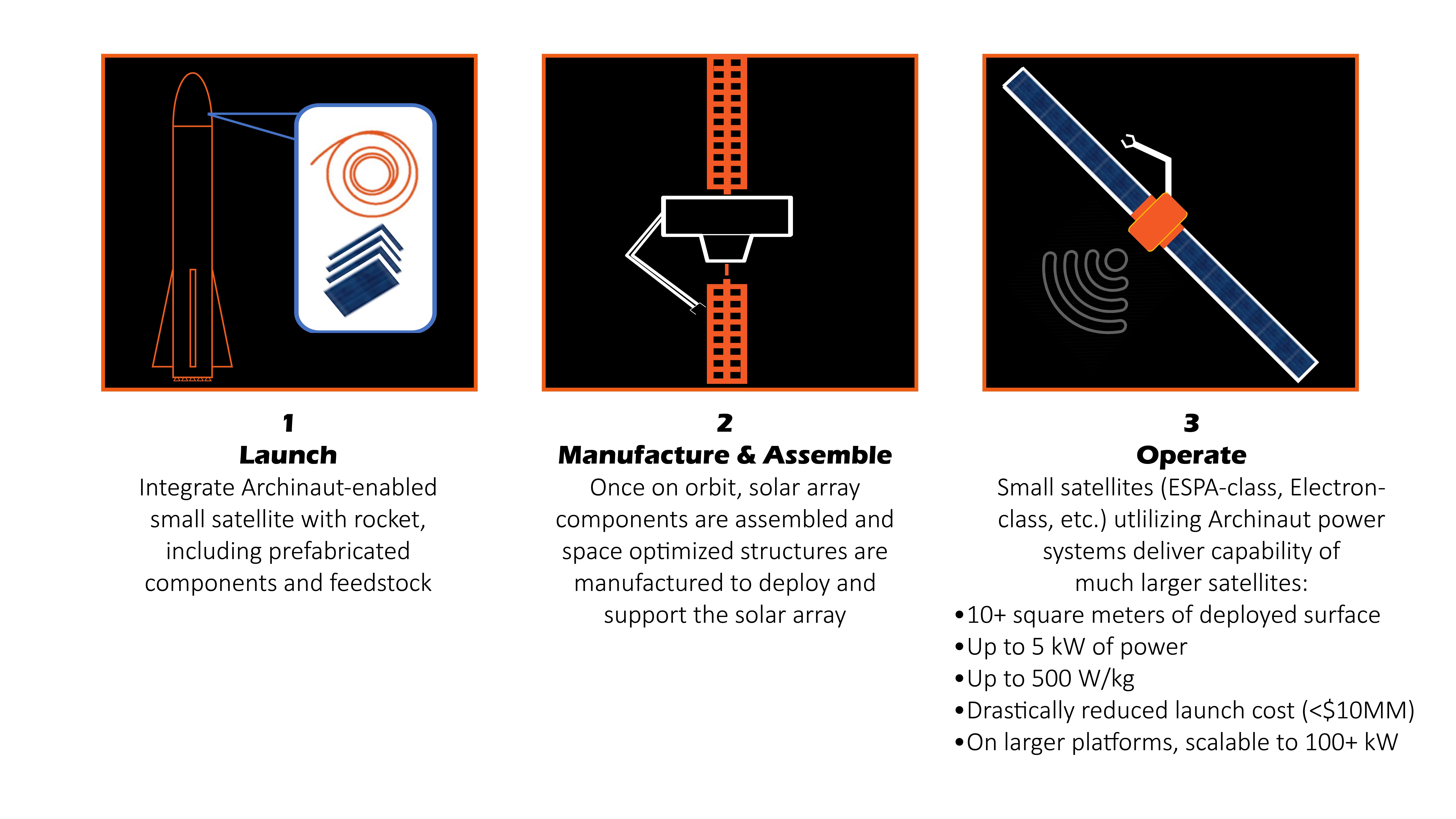

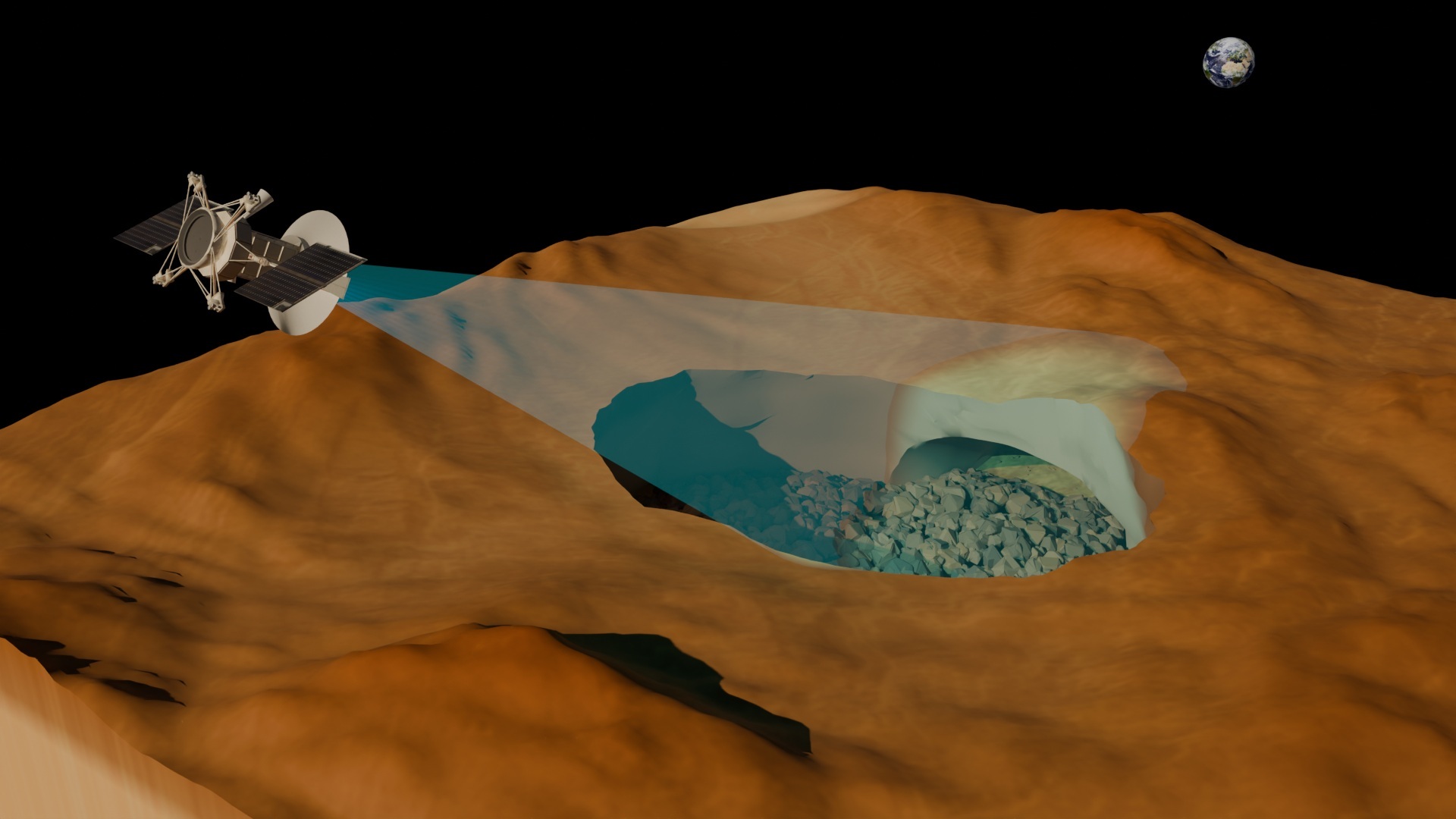

One of the first big jobs for the Archinaut in-space assembly robot being developed by California startup Made In Space may involve outfitting small satellites with large solar-power systems in Earth orbit.

Such work could boost the power potential of spacecraft in the 330-lb. to 660-lb. (150 to 300 kilograms) range by a factor of five or more, allowing them to take on duties previously limited to larger satellites, company representatives said. [Satellite Quiz: How Well Do You Know What's Orbiting Earth?]

"Deploying these power-intensive payloads on small satellites is game-changing, because these platforms cost an order of magnitude less to build and launch and can be fielded much more rapidly than 1,000-kilogram-plus satellites," Made In Space CEO Andrew Rush said in a statement.

Archinaut, which Made In Space is developing under a NASA "tipping points technologies" contract, features a 3D printer and robotic manipulator arms. Once it's up and running, Archinaut will be able to perform a variety of tasks off-Earth, from repairing satellites to building large structures such as space telescopes, company representatives have said.

For the smallsat-power application, Archinaut would be built into (and therefore launch with) the client satellite, Rush said. The satellite's solar cells would also be stowed aboard, along with raw materials for Archinaut's 3D printer.

"Once we get on orbit, we use our robotic manipulators to pull out the appropriate part and make an assembly, and then manufacture the space-optimized structure that would support the solar array," Rush told Space.com.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

This approach would allow the construction of much larger power systems compared to the traditional method, which involves unfolding tightly packed, previously assembled solar arrays, Rush said.

Made In Space has proposed in-space trials of this capability to several potential customers, including NASA, he added.

"If that's picked up, then you'll see demonstrations of this in three to 3.5 years," Rush told Space.com.

Made In Space already has some off-Earth work under its belt. For example, the company has built and launched two 3D printers to the International Space Station (ISS). NASA now owns the first machine, but Made In Space retains control of the second, called the Additive Manufacturing Facility, and leases it out to commercial customers.

Also on the ISS is a Made In Space machine designed to produce a high-value fiber-optic cable called ZBLAN. Gravity induces imperfections in ZBLAN manufactured here on Earth, and Made In Space therefore thinks it can produce — and eventually sell — a higher-quality version of the stuff on orbit.

The mini ZBLAN factory launched to the ISS aboard a SpaceX Dragon capsule last December and has seen significant action, Rush said.

"We've produced material — manufactured the very first ZBLAN off the face of the planet — and gotten some really good initial results," he said. "We're putting [the machine] through its paces and proving out the system."

Follow Mike Wall on Twitter @michaeldwall and Google+. Follow us @Spacedotcom, Facebook or Google+. Originally published on Space.com.

Michael Wall is a Senior Space Writer with Space.com and joined the team in 2010. He primarily covers exoplanets, spaceflight and military space, but has been known to dabble in the space art beat. His book about the search for alien life, "Out There," was published on Nov. 13, 2018. Before becoming a science writer, Michael worked as a herpetologist and wildlife biologist. He has a Ph.D. in evolutionary biology from the University of Sydney, Australia, a bachelor's degree from the University of Arizona, and a graduate certificate in science writing from the University of California, Santa Cruz. To find out what his latest project is, you can follow Michael on Twitter.