The world's first wooden satellite will launch this year

A Scandinavian cubesat will test how plywood withstands the space environment.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Twice a month

Strange New Words

Space.com's Sci-Fi Reader's Club. Read a sci-fi short story every month and join a virtual community of fellow science fiction fans!

The world’s first "wooden satellite" is preparing to launch this year.

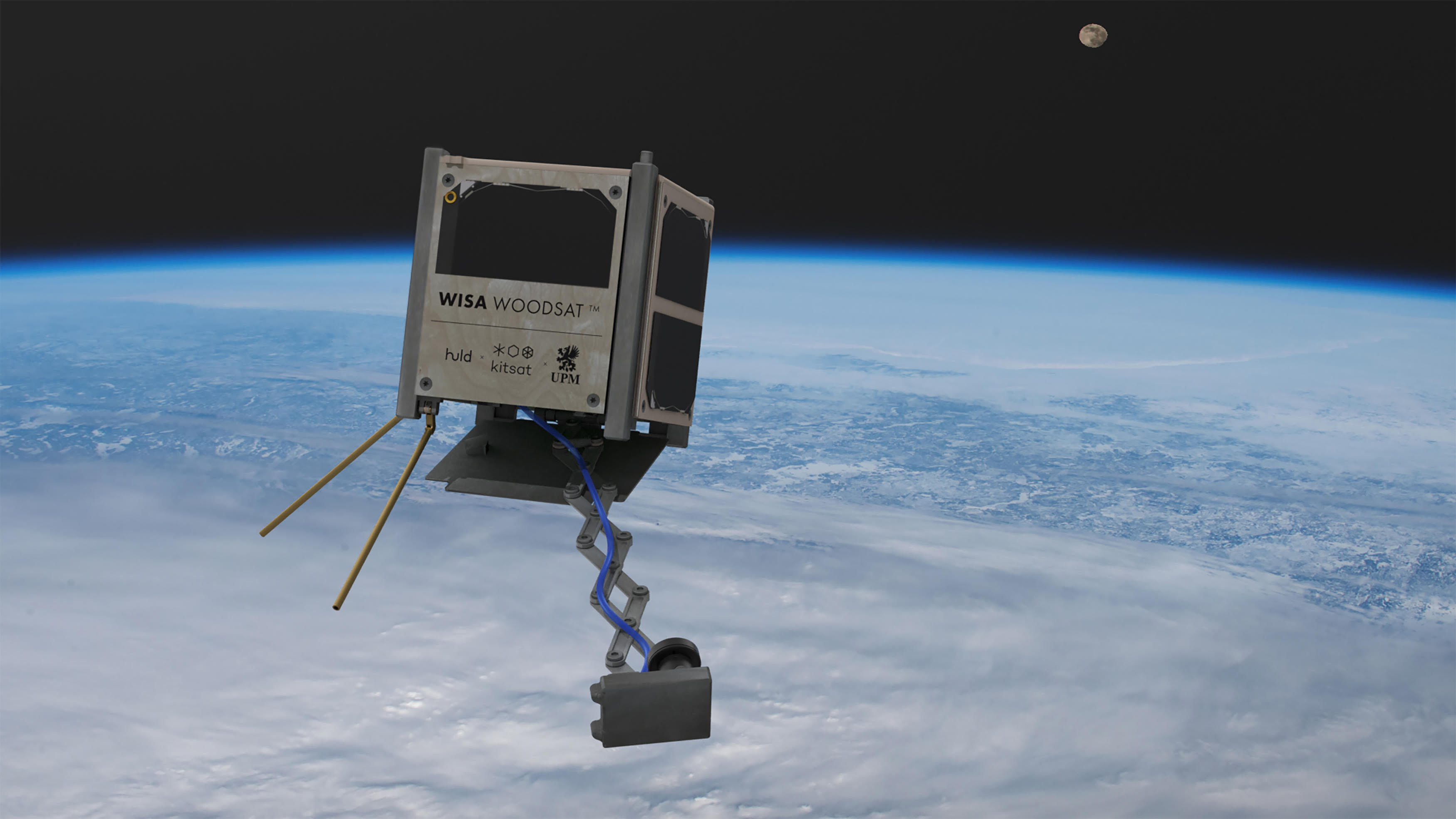

WISA Woodsat, a nanosatellite that measures 4 by 4 by 4 inches (10 by 10 by 10 centimeters) and weighs about 2.2 lbs. (1 kilogram), uses a special type of coated plywood (called WISA) for its surface panels. The wooden satellite will launch as part of a mission, designed by Arctic Astronautics, a Finnish company manufacturing cubesat kits for students. The aim of the mission is to test the behavior and durability of these plywood panels in the extreme conditions of space and assess its suitability for future missions.

The satellite will be outfitted with two cameras, one of which will be attached to a metal selfie stick, allowing the mission team to observe how the satellite's plywood surface changes in the space environment.

Related: Startup bluShift Aerospace launches its 1st commercial biofuel rocket from Maine

"The base material for plywood is birch, and we're using basically just the same as you'd find in a hardware store or to make furniture," Woodsat chief engineer Samuli Nymanm, who is also the Arctic Astronautics co-founder, said in a statement. "The main difference is that ordinary plywood is too humid for space uses, so we place our wood in a thermal vacuum chamber to dry it out. Then we also perform atomic layer deposition, adding a very thin aluminum oxide layer."

So how can a satellite made with wood survive outer space?

Aluminum oxide, a chemical compound typically used to encapsulate electronics, will help to prevent the wood from releasing any gas in the space environment, according to Nymanm. It will also protect the surface against the exposure to corrosive atomic oxygen, which can be found at the fringes of the Earth's atmosphere. This type of oxygen, created when strong UV radiation from the sun splits normal oxygen molecules, was first discovered after it damaged the thermal blankets of NASA's early Space Shuttle missions.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

This atomic oxygen will likely darken the plywood panels. The satellite, however, should survive in the extreme environment, the company said in the statement.

In addition to the coating, engineers will also test various varnishes and lacquers on sections of the wood.

Aside from the two cameras, the satellite will also carry a set of pressure sensors that will monitor pressure in onboard cavities especially in the spacecraft’s first days in orbit.

The satellite will also run an experiment that will test the use of a novel 3D-printed electrically conductive plastic material, which could pave the way for possible future onboard 3D printing of power and data cables directly in space, the European Space Agency, which helps Arctic Astronautics test the satellite, said in a separate statement.

The satellite, which is powered by nine small solar cells, will be equipped with an amateur radio payload that will allow hobbyists to relay radio signals and images around the globe.

Arctic Astronautics previously flew a wooden cubesat on a weather balloon, which, however, didn’t pass the karman line, the boundary between the atmosphere and space. The current Woodsat is a new generation of the technology. It will be launched into its 300 and 370 miles (500 and 600 kilometers) polar orbit on Rocket Lab's Electron rocket in November of this year.

UPM Plywood, which manufactures plywood, and technology design company Huld, are partners on the project.

"We foresee a lot of possibilities in the future by using the knowhow developed in this mission," Matti Anttila, Space Business Development Director from Huld, said in the statement.

Follow Tereza Pultarova on Twitter @TerezaPultarova. Follow us on Twitter @Spacedotcom and on Facebook.

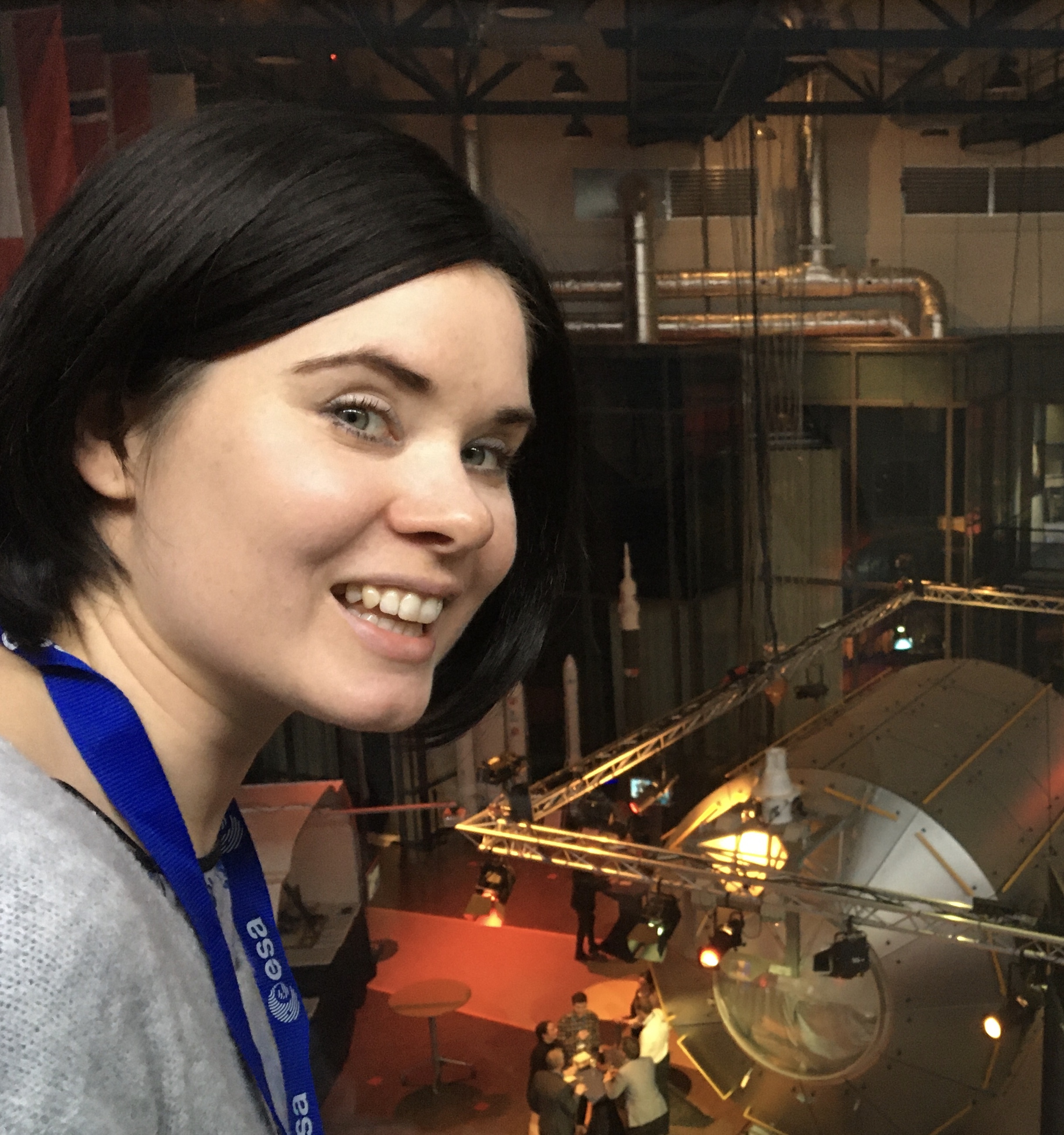

Tereza is a London-based science and technology journalist, aspiring fiction writer and amateur gymnast. She worked as a reporter at the Engineering and Technology magazine, freelanced for a range of publications including Live Science, Space.com, Professional Engineering, Via Satellite and Space News and served as a maternity cover science editor at the European Space Agency.