Photos: NASA's Orion Spacecraft Heat Shield on Display

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Twice a month

Strange New Words

Space.com's Sci-Fi Reader's Club. Read a sci-fi short story every month and join a virtual community of fellow science fiction fans!

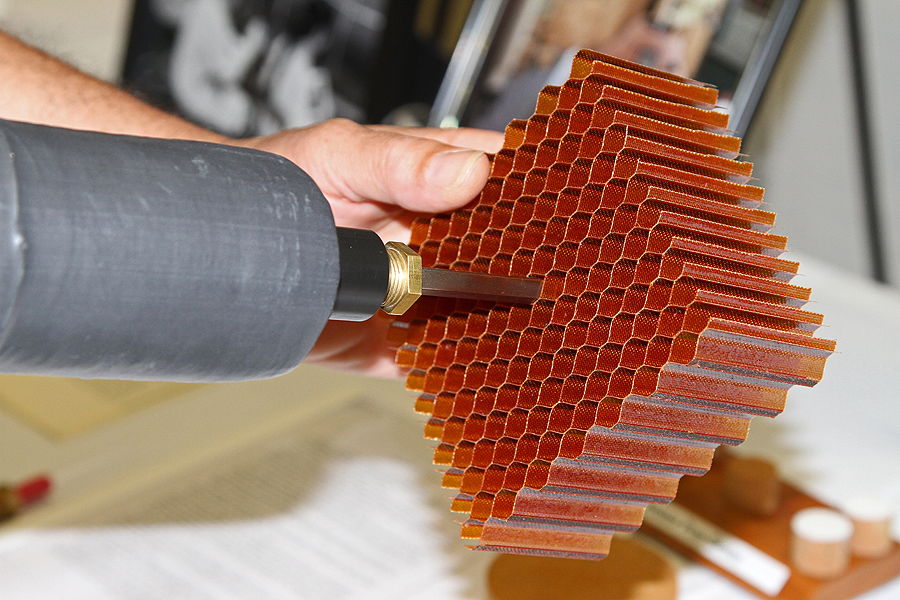

Close-up of Worker with Avcoat Gun

Each Avcoat-filled cell in the heat shield’s honeycomb structure is inspected by a robotic X-ray scanner. Once the Avcoat application is complete, the heat shield will be machined, sealed, primed, and finally painted before it is shipped to NASA’s Kennedy Space Center in Florida for installation on the Orion crew module.

Engineer with Avcoat Gun

Textron engineer Anthony Cudia demonstrates the caulk-gun-like tool that is used to inject Avcoat into the honeycomb cells. Cudia originally helped develop the gun for NASA’s Apollo program.

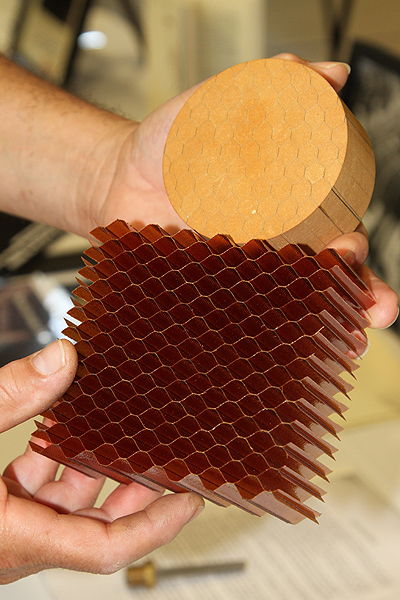

Close-Up of Orion Heat Shield’s Honeycomb

The fiberglass honeycomb is bonded to the heat shield and provides structural reinforcement to the ablative Avcoat material so it doesn’t crack. Engineers have designed the heat shield to withstand extreme temperatures during re-entry as well as the impact of ocean splashdown.

Finished and Unfinished Honeycomb Compared

This view shows a bare honeycomb structure and one that has been filled with Avcoat using Textron’s “gunning” process.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Imelda B. Joson is a veteran astrophotographer, as well as an eclipse chaser and world traveler. With her husband, Edwin Aguirre, she has organized, led and/or participated in 11 solar eclipse expeditions in North America, Asia and Africa. The pair also conceptualized and created National Astronomy Week, an event that celebrates and publicizes astronomy in the Philippines.