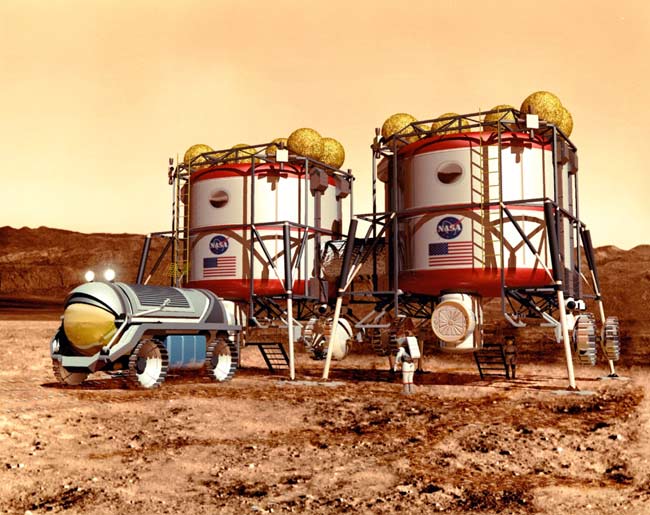

Micromachines to Produce Propellant and Air on Mars

Breaking space news, the latest updates on rocket launches, skywatching events and more!

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Daily Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Once a month

Watch This Space

Sign up to our monthly entertainment newsletter to keep up with all our coverage of the latest sci-fi and space movies, tv shows, games and books.

Once a week

Night Sky This Week

Discover this week's must-see night sky events, moon phases, and stunning astrophotos. Sign up for our skywatching newsletter and explore the universe with us!

Twice a month

Strange New Words

Space.com's Sci-Fi Reader's Club. Read a sci-fi short story every month and join a virtual community of fellow science fiction fans!

Two teamsof researchers are hoping their tiny devices will mean big leaps for futureMars-bound humans, allowing them to carry powerful computers and generate lifesupport materials from the planet's atmosphere.

In onecorner, NASA-funded scientists are tweaking microtechnology to produce compactsystems that produce breathing oxygen or rocket propellant, vital components ofany manned space mission.

"We'relooking at collecting the carbon dioxide from the Martian atmosphere and breakingit down for [crew needs]," said Batelle researcher Kriston Brooks, principalinvestigator of the study at Pacific Northwest National Lab (PNNL), where NASAhas awarded a contract to develop the technology.

The goal,Brooks added, is to wrangle microtechnology into a usable system that wouldgenerate propellant for astronauts aboard a manned mission to Mars by 2030, agoal set by NASA's space vision of renewing human space exploration outsideEarth orbit.

"It's allabout helping to reduce the cost of missions for robotic sample returns andeven human space missions," said NASA's Tom Simon, a systems engineer forin-situ resource utilization at Johnson Space Center. "We're hoping that thework will be a great kick-start for using resources on Mars to enable us tomeet our budget goals and constraints for exploration."

Meanwhile,two Purdue University researchers are adapting microchannel heat sinks - small copperplates lined with numerous grooves each three times the width of a human hair -with conventional refrigeration methods to build more efficient cooling systems.

"Themicrochannel heat sinks are absolutely ideal for those situations," said thermalengineer Issam Mudawar, the study's leader and a Purdue mechanical engineeringprofessor, in a telephone interview. "Though our immediate target is bothcomputer chips and defense applications."

Breaking space news, the latest updates on rocket launches, skywatching events and more!

Settingup shop off-planet

NASA hasset aside $13.7 million for Brooks' four-year study, which engineers hope proveuseful not just for Mars missions, but also lunar spaceflights and space stationliving as well.

Using localresources could reduce the cost of a moon or Mars mission by about 40 percentaccording to NASA studies, Simon told SPACE.com, adding that lunarresource-based technology is also under scrutiny.

"We'rehoping to be able to support by 2010 a small demo mission that not only producesjust a couple of grams of oxygen, but will also be able to tell what water ison the moon," Simon said.

Currently carbondioxide collected by the space station's air scrubbers and hydrogen produced bythe station's Elektron oxygen generator are currently are dumped overboard, butSabatier reactors - which generate methane from carbon dioxide - could helpastronauts recover oxygen from what has to date been treated as waste gas, headded.

Microchannelsurfing

At theheart of Brooks and Mudawar's studies are advances with microchannels,which have allowed researchers to squeeze chemical and thermal processes intoever-smaller packages.

"Whatreally got this started is microchip technology," Brooks told SPACE.com."We thought, 'well, if we can make microchips so small, why can't we do the samething chemically.'"

Withmultiple grooves separated by just 200 microns or so apart, microchannel platesoffer improved heat and mass transfer rates. Since the spaces between groovewalls are so small, the effects of gravity give way to other forces, similar towater's capillary action, making the technology apt for space applications, theresearchers said.

"You alsohave the advantage of redundancy," Brooks said, adding that the processes requiredto scale up from one microchannel to a 1,000-microchannel system are simplerthan other processing methods.

ForMudawar, the differences in fluid flow between microchannels and the moreconventional tubing used for heat sinks has allowed the development of evensmaller cooling systems for electronics.

MultifacetedMicroCATS

In order toproduce oxygen or propellant for a spacecraft, Brooks is developing a closed-loopsystem of heat exchangers, condensers, phase separators and other tools into aworking microchemical and thermal system (MicroCATS) device about one cubicfoot in size.

Once theindividual components are tested, they will be integrated into a breadboard-sized system and tested in microgravity aboard NASA's KC-135 aircraft, aswell as inside atmospheric chambers to simulate the Mars atmosphere andtemperature environment.

Brookshopes the test will lead to a final setup, known as an In-Situ PropellantProduction system (ISPP), that could sit outside a spacecraft on the Martiansurface, absorbing carbon dioxide, then heating it up and passing it through aseries of small reactors to separate the gas into methane and water, which isultimately broken down into oxygen and hydrogen.

"Our goalis to be about one-third the weight of conventional systems," Brooks said. "Hopefully,we'd be able to catch a ride on a mission that's going to Mars and people cantest this out."

The oxygenand methane can be cryogenically stored in separate tanks - possibly even thesame ones used to hold fuel for the trip to Mars - and later be used as propellant,Brooks said, adding that the system could also bolster life support as well.

"Forexample, on a space suit you could use it to collect carbon dioxide andregenerate it into oxygen," Brooks said. "What they do now aboard the spacestation is collect the carbon dioxide, absorb it then replace the [scrubbers]...weneed to be able to close the loop on life support."

Buildinga cooler system

At PurdueUniversity, Mudawar and doctoral student Jaeson Lee have already demonstratedthe potential of their microchannel heat sinks.

"We reallyhave a working system now," said Mudawar, whose study is funded by the U.S.Office of Naval Research.

Two researchpapers based on the work appeared in a recent edition of the InternationalJournal of Heat and Mass. Mudawar has also tested past heat sinks aboardNASA's KC-135 aircraft in weightless experiments for a variety of space systems.

Mudawar andLee were able to successfully use a one-inch square copper microchannel plateto serve the same evaporative cooling function as the one-meter long tubingused in a refrigerator. "The issue now is going to be packaging the cooling systemaround the device."

While Mudawar'sheat sink still requires a refrigerant to function - the researchers usedR134a, which is found in household refrigerators and air conditioners - it offersmuch higher performance than conventional fans or dissipation metal fins. Futuremilitary weapons systems, such as advanced lasers, may require heat sinks capableof dissipating up to 10,000 watts per centimeter that current methods may notbe able to handle efficiently.

"We werevery satisfied with this technology," Mudawar said.

Tariq is the award-winning Editor-in-Chief of Space.com and joined the team in 2001. He covers human spaceflight, as well as skywatching and entertainment. He became Space.com's Editor-in-Chief in 2019. Before joining Space.com, Tariq was a staff reporter for The Los Angeles Times covering education and city beats in La Habra, Fullerton and Huntington Beach. He's a recipient of the 2022 Harry Kolcum Award for excellence in space reporting and the 2025 Space Pioneer Award from the National Space Society. He is an Eagle Scout and Space Camp alum with journalism degrees from the USC and NYU. You can find Tariq at Space.com and as the co-host to the This Week In Space podcast on the TWiT network. To see his latest project, you can follow Tariq on Twitter @tariqjmalik.