Space Verdict

The Elegoo Neptune 3 Plus offers excellent print quality, auto-leveling and a great size build platform at a reasonable price. It's incredibly well built, easy to use, and prints almost silently too. We seriously can't find a single fault with it, so it's an easy recommendation from us.

Pros

- +

Large build volume

- +

Silent steppers for near silent printing

- +

Auto leveling

- +

Excellent print quality

Cons

- -

Honestly, we can't think of anything

Why you can trust Space.com

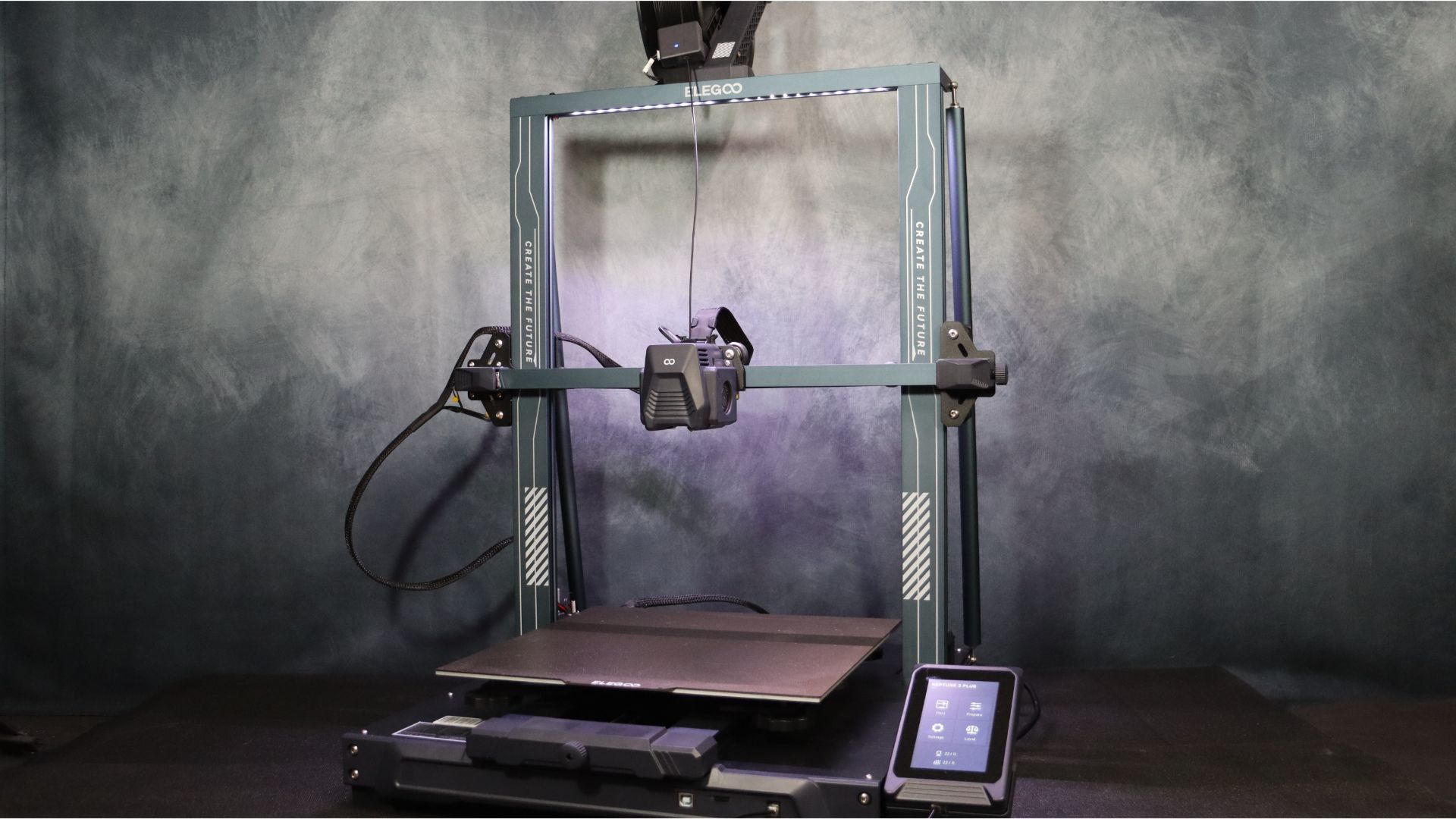

Elegoo formally unveiled its improved Neptune 3 Series, which consists of three models with various print volumes, late last year in November. The Elegoo Neptune 3 Plus is the middle option in terms of size and cost; it's ideal for people who need more print volume than what the majority of low-cost 3D printers can provide, but don't need all the bells and whistles of the top-end model.

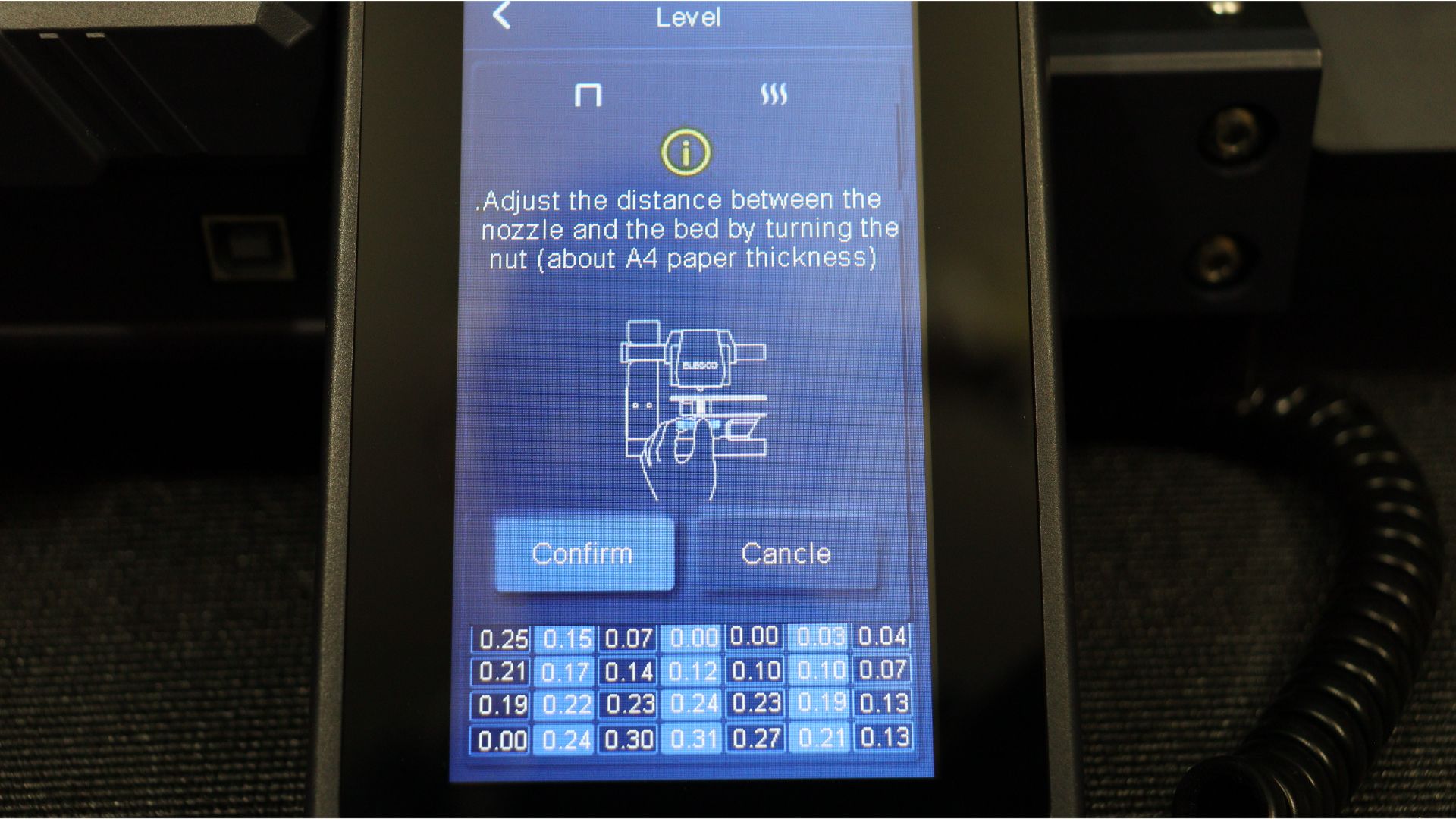

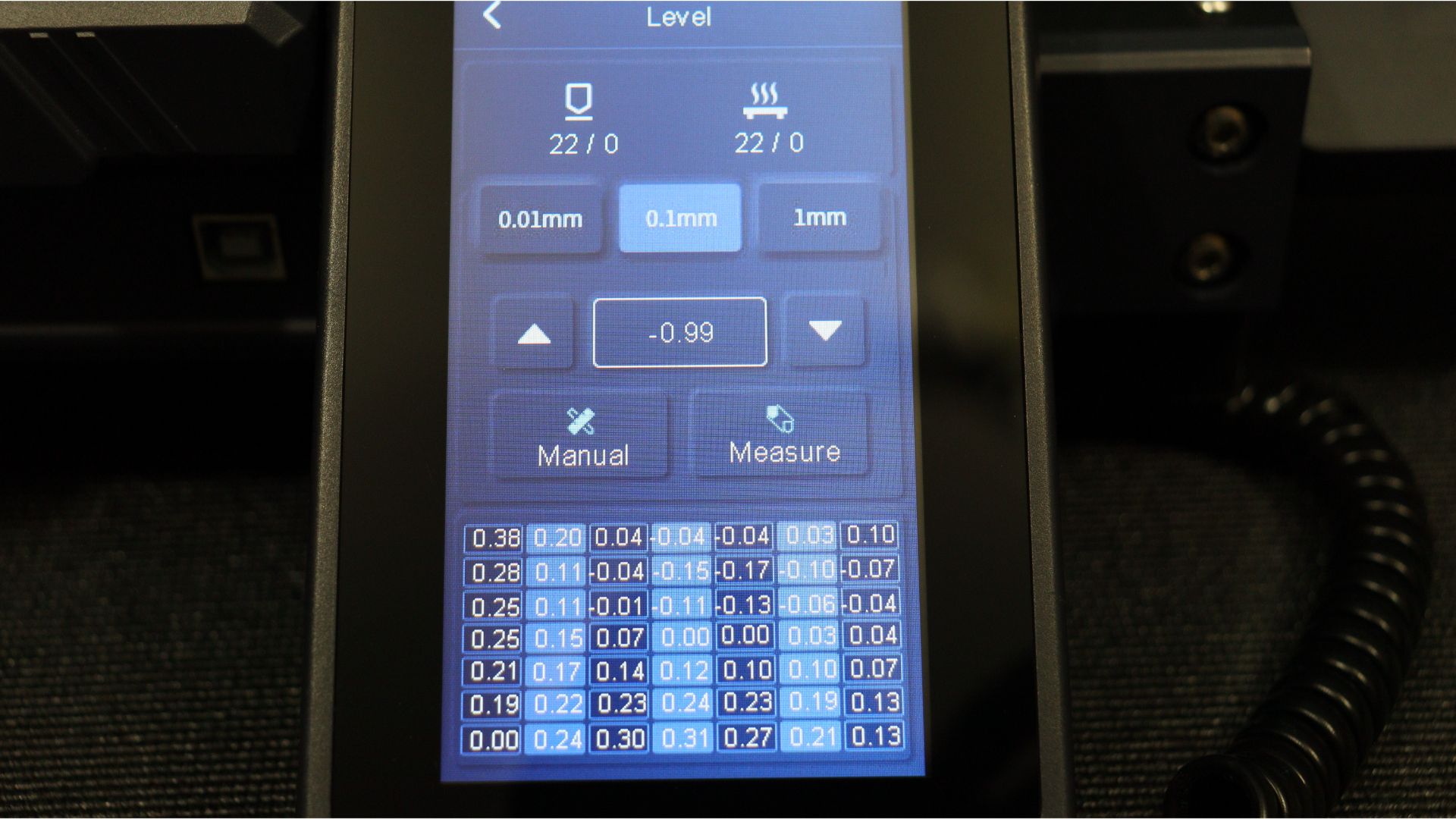

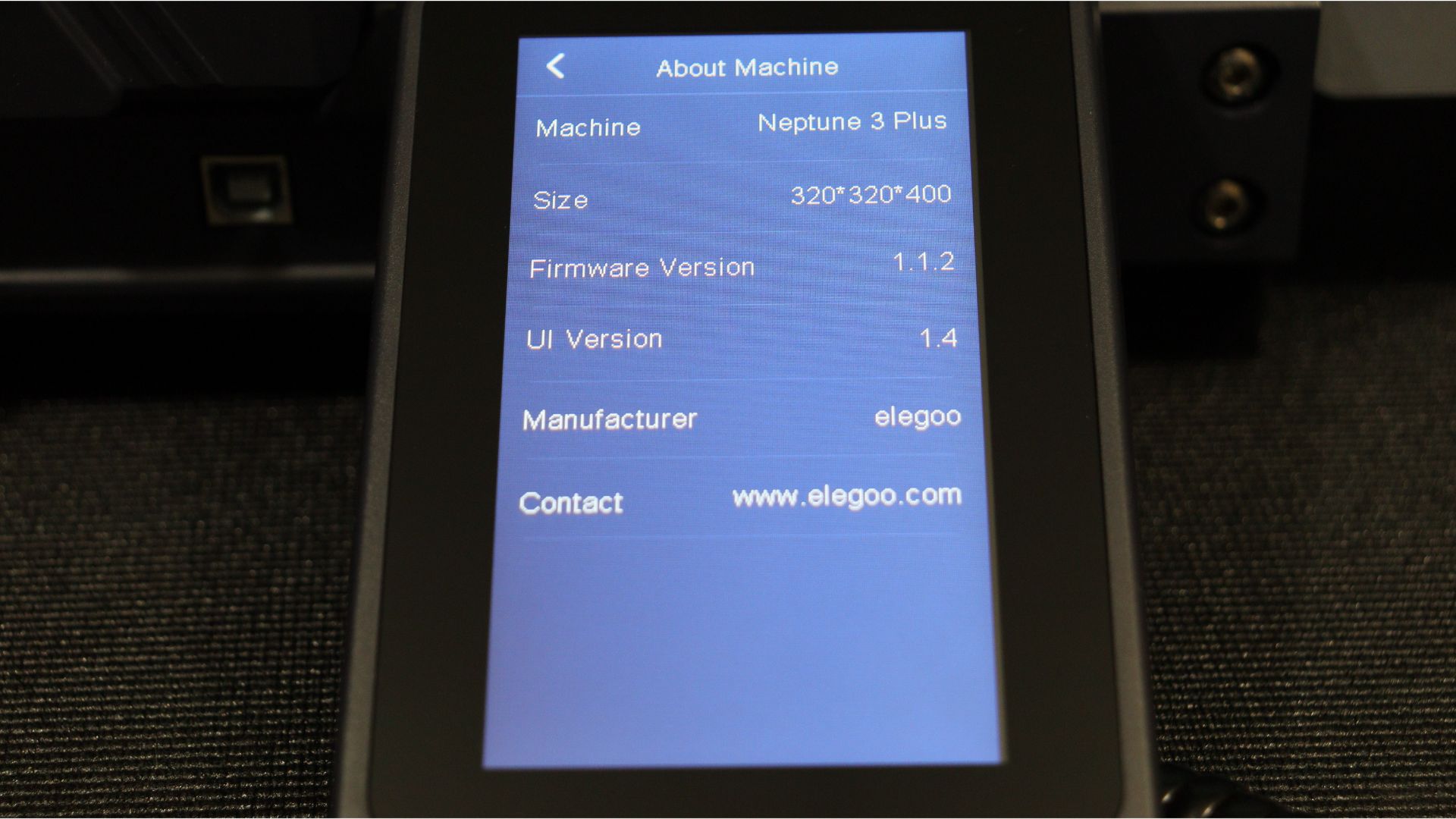

On paper, the Elegoo Neptune 3 Plus has a lot going for it with a build capacity of 320 x 320 x 400 mm and a direct drive extruder – perfect for challenging-to-print materials like TPU. It also has a swanky 49-point auto-levelling system that can be manually adjusted too, so you can get started quickly and still have the option to really fine tune your bed.

When compared to other 3D printers in the same price range, the Neptune Plus is looking to be one of the best 3D printers available right out of the box thanks to its outstanding feature set, excellent performance, and competitive pricing. Whether you're looking for something to print out Star Wars cosplay pieces, spaceship models, or anything else, the Neptune 3 Plus is worth considering.

Elegoo Neptune 3 Plus: Design & setup

Like most FDM printers, the Elegoo Neptune 3 Plus is delivered to you 90% constructed, and the remaining assembly requirements are minimal. The upright assembly must first be fastened to the printer base using the four included screws.

Printer base

Z and X axis assembly

LCD touch screen Magnetic base

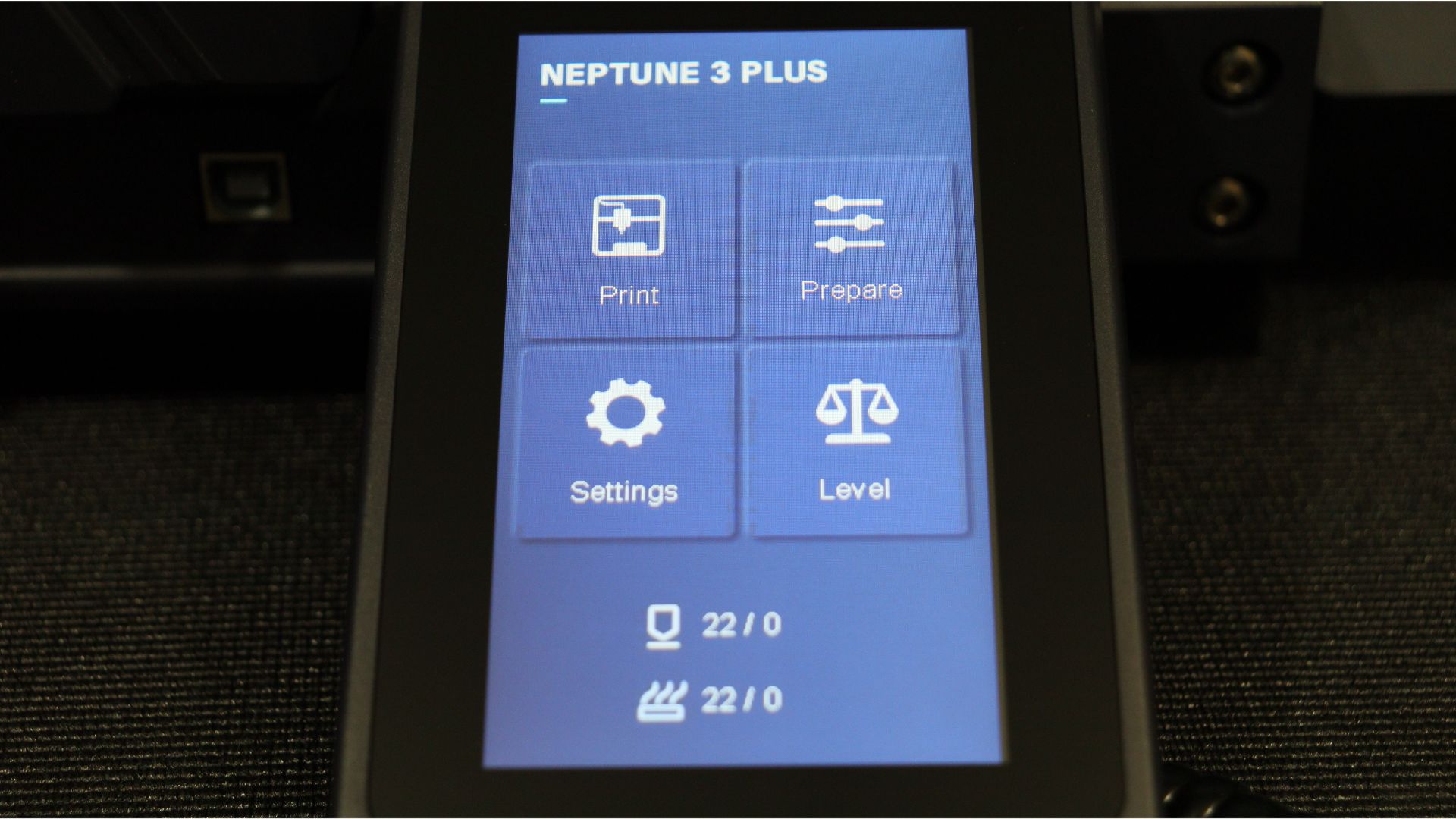

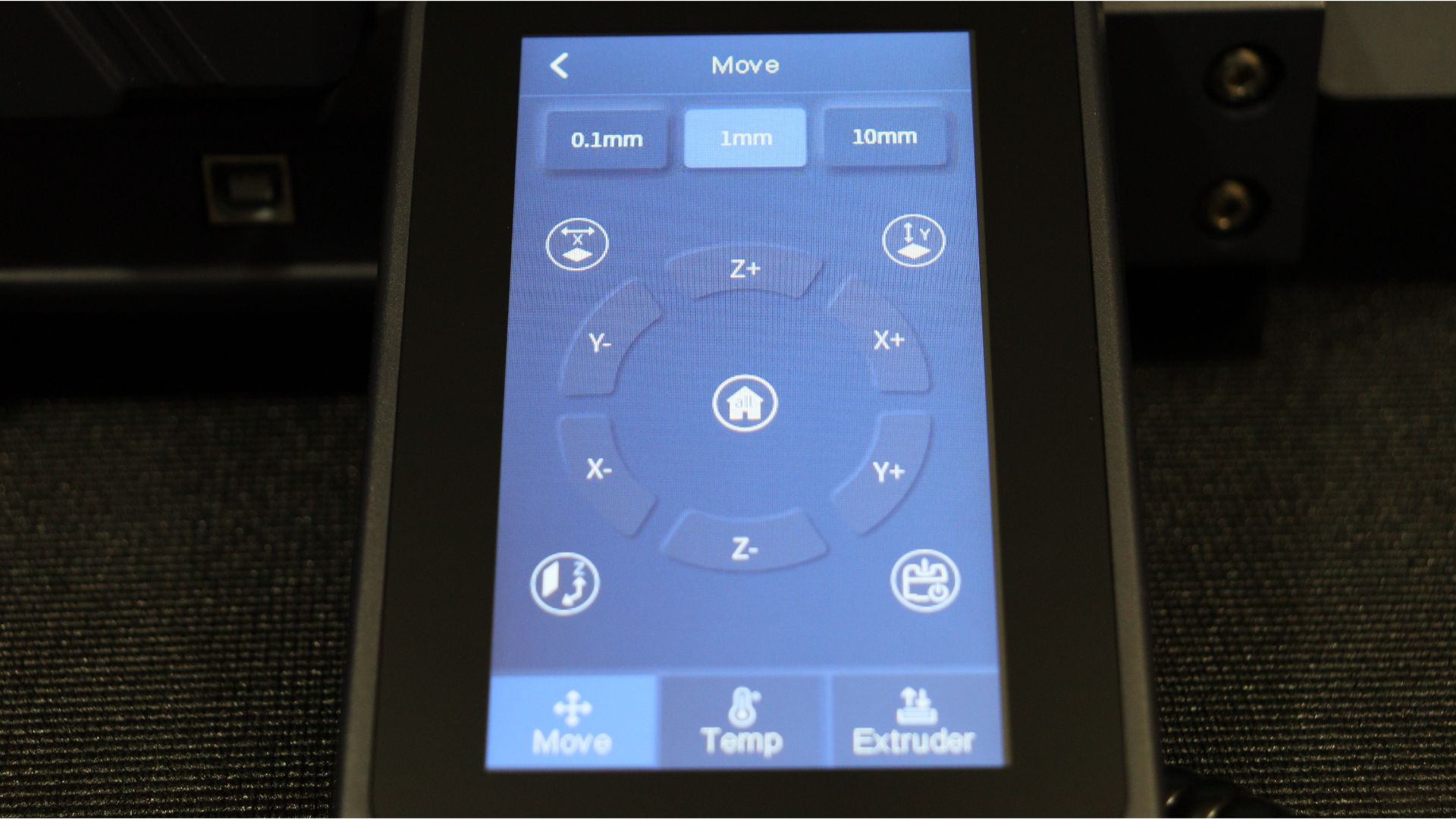

4.3-inch LCD touchscreen

Spool holder

Filament run out sensor

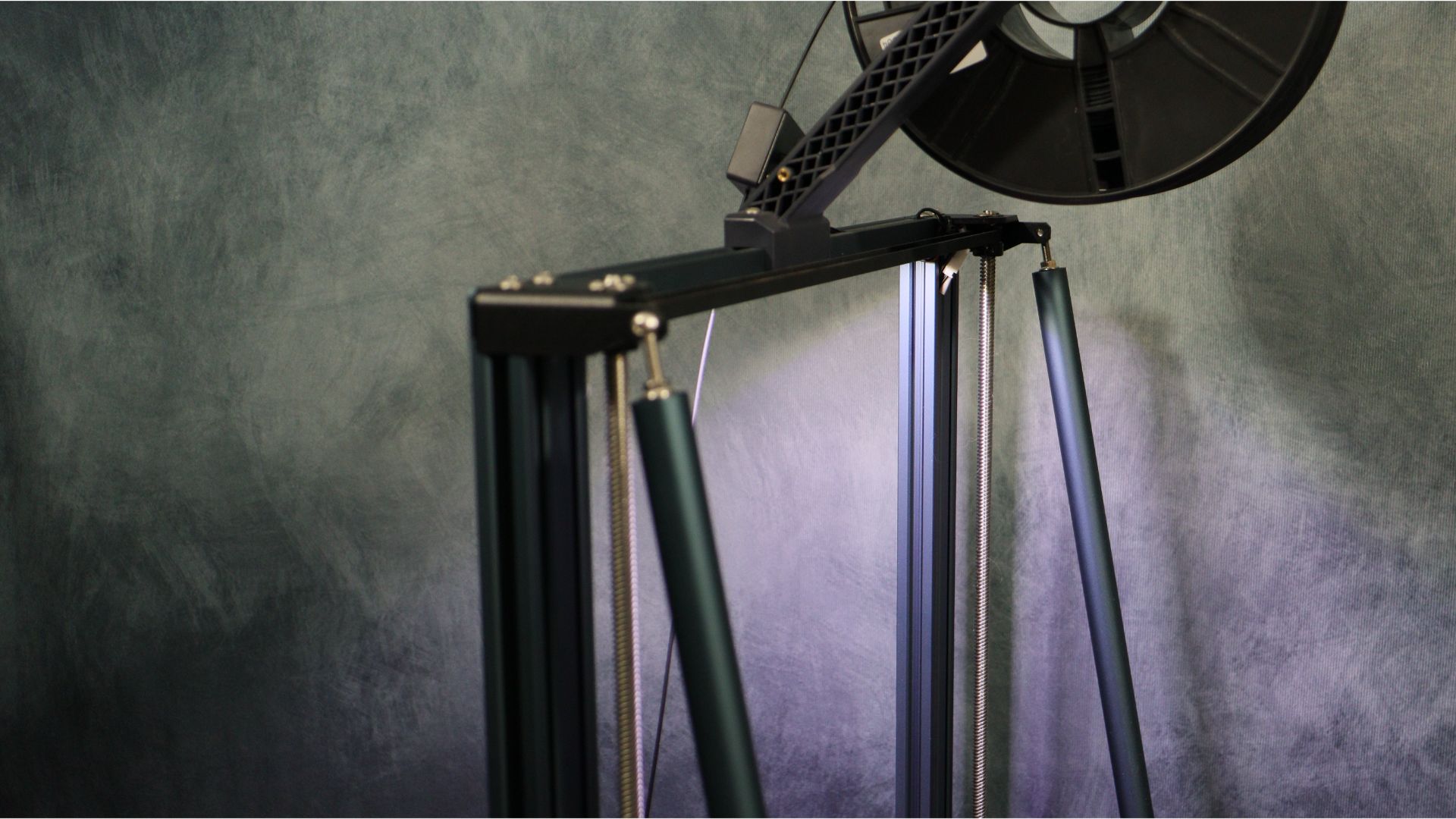

Tie Rod supports

Power cable

Tool kit for assembly

Plastic scraper

side cutters

USB cable

Spare nozzles

USB reader

The LCD screen is then plugged into the front of the printer, secured in the magnetic cradle, and attached to the base. The filament run out sensor and spool holder can now be attached to the top of the printer. The support tie rods on the printer's rear are then fastened to the brackets on the top of the printer. Elegoo has marked all of our connections, so the last step is as simple and straightforward.

Make sure to leave adequate space when attaching the cable clip holding the hotend assembly wiring harness so that there won't be any problems when the print head reaches the far right side.

We can turn on the printer as soon as you're through with the assembly. The bed must first be levelled manually before the auto level is used to check 49 locations on the bed and store the mesh. Once completed we are ready to start our first print.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

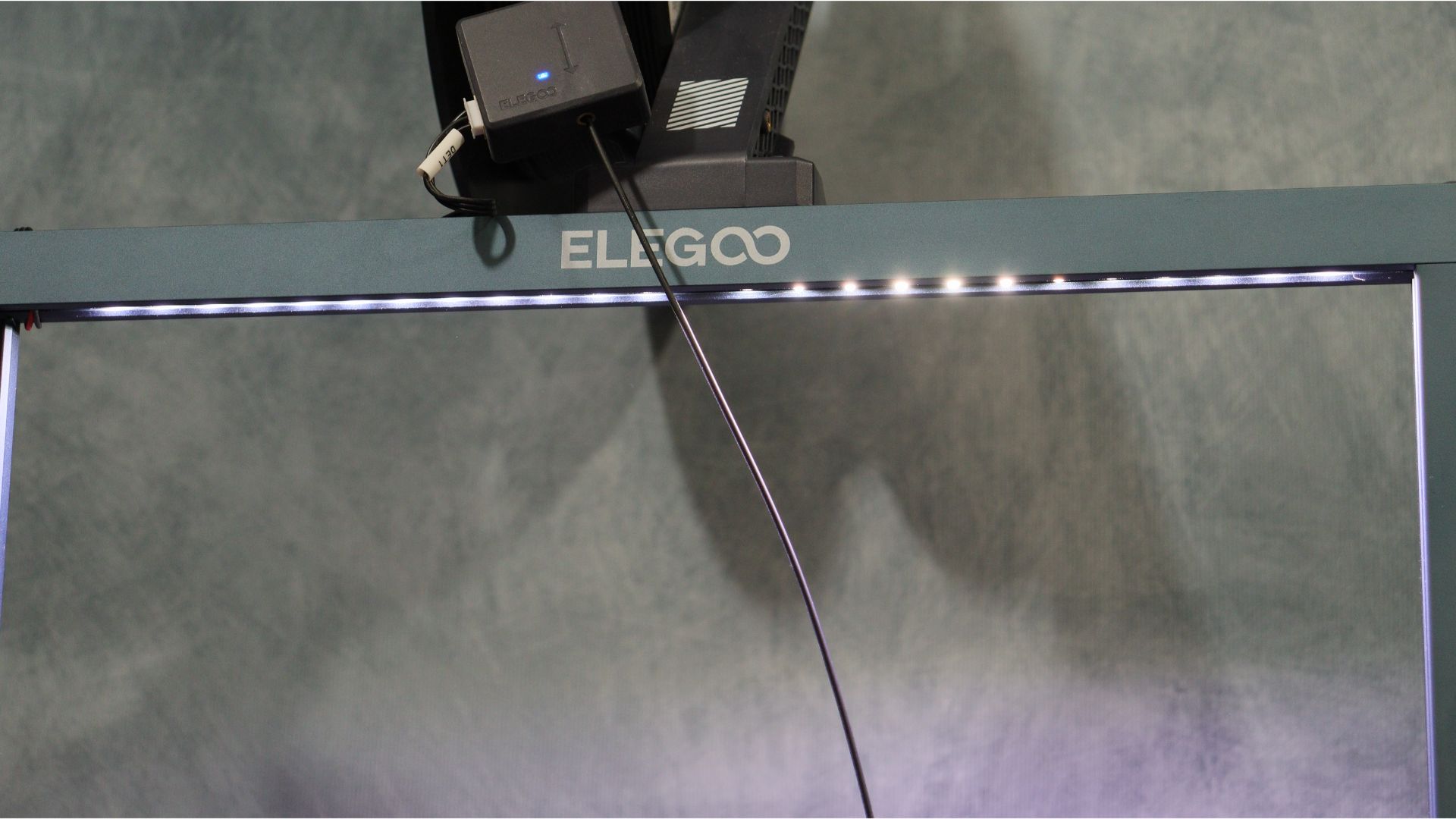

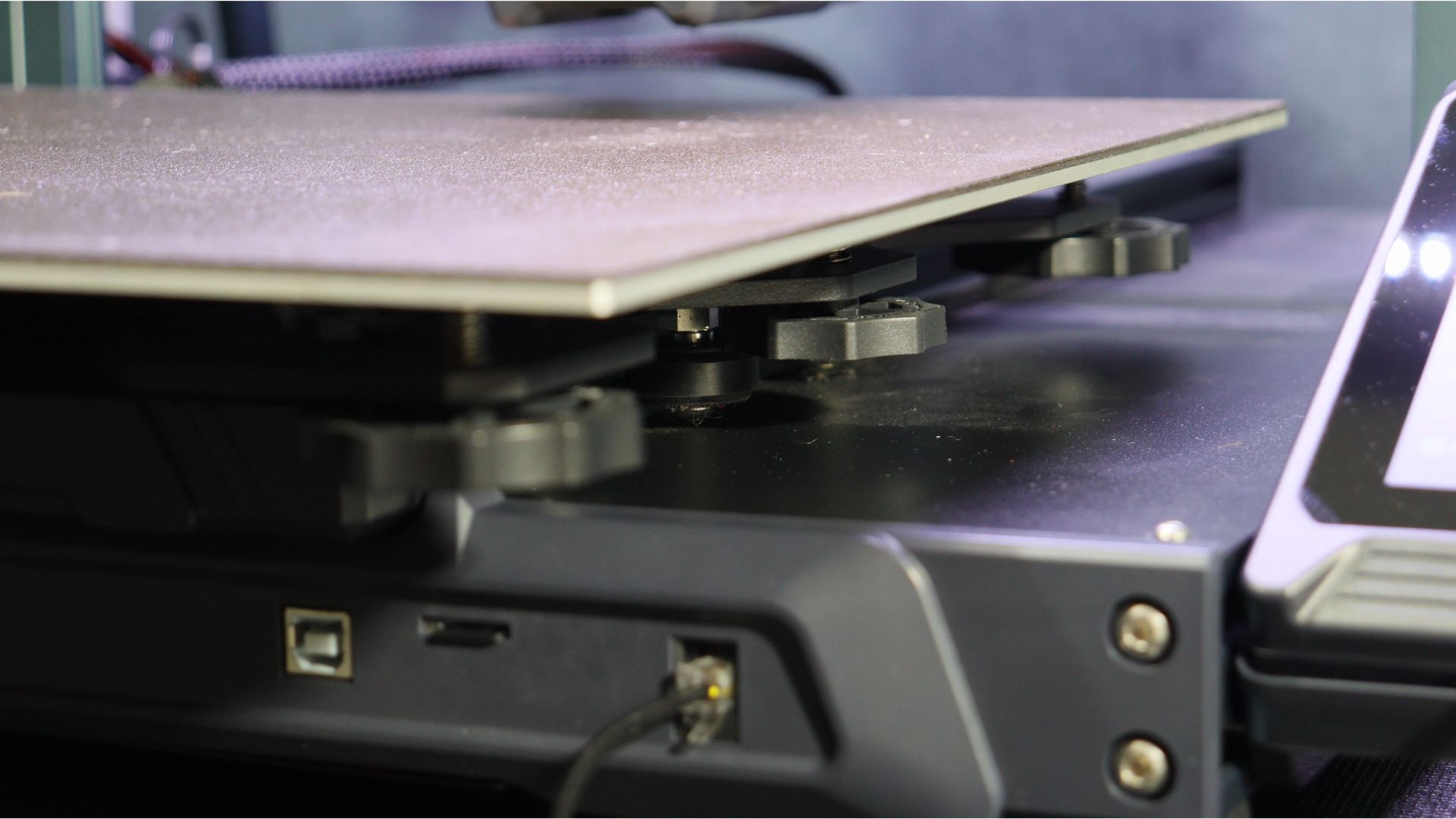

The Neptune 3 Plus's design was mostly carried over from the Neptune 3 Pro, with a few minor adjustments made to account for the higher build volume. The two support tie rods on the back of the printer which help to reduce any wobble, a second Z axis stepper with a timing belt to keep the Z axis in sync for those models that will use the 400mm height, and six levelling knobs on the platform to ensure you get the perfect level are the main changes. A second rail was also added to the Y axis to support the larger bed. The top rail of the printer also has an LED light strip that performs an excellent job of illuminating the work area.

Elegoo Neptune 3 Plus: Specs & features

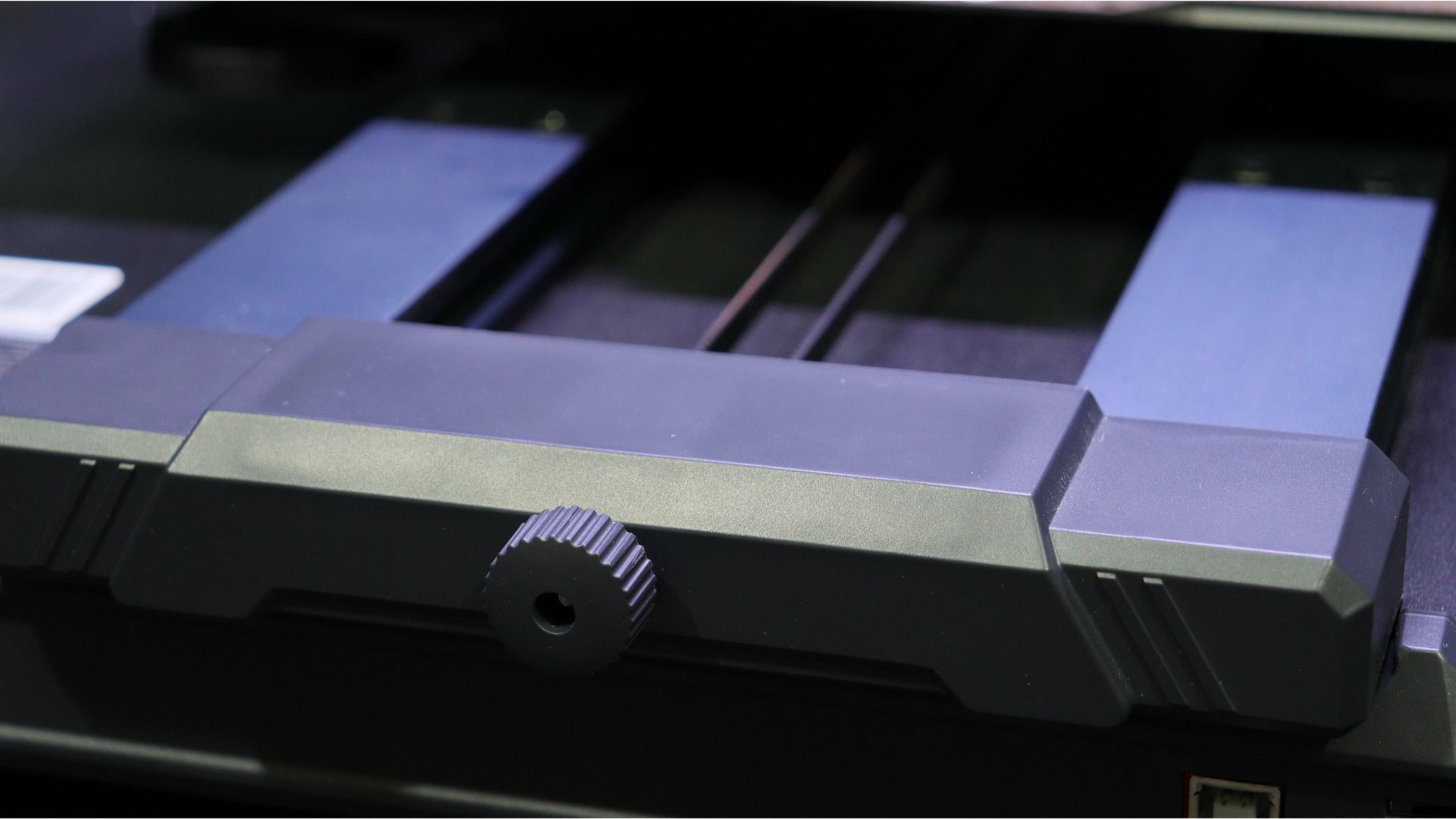

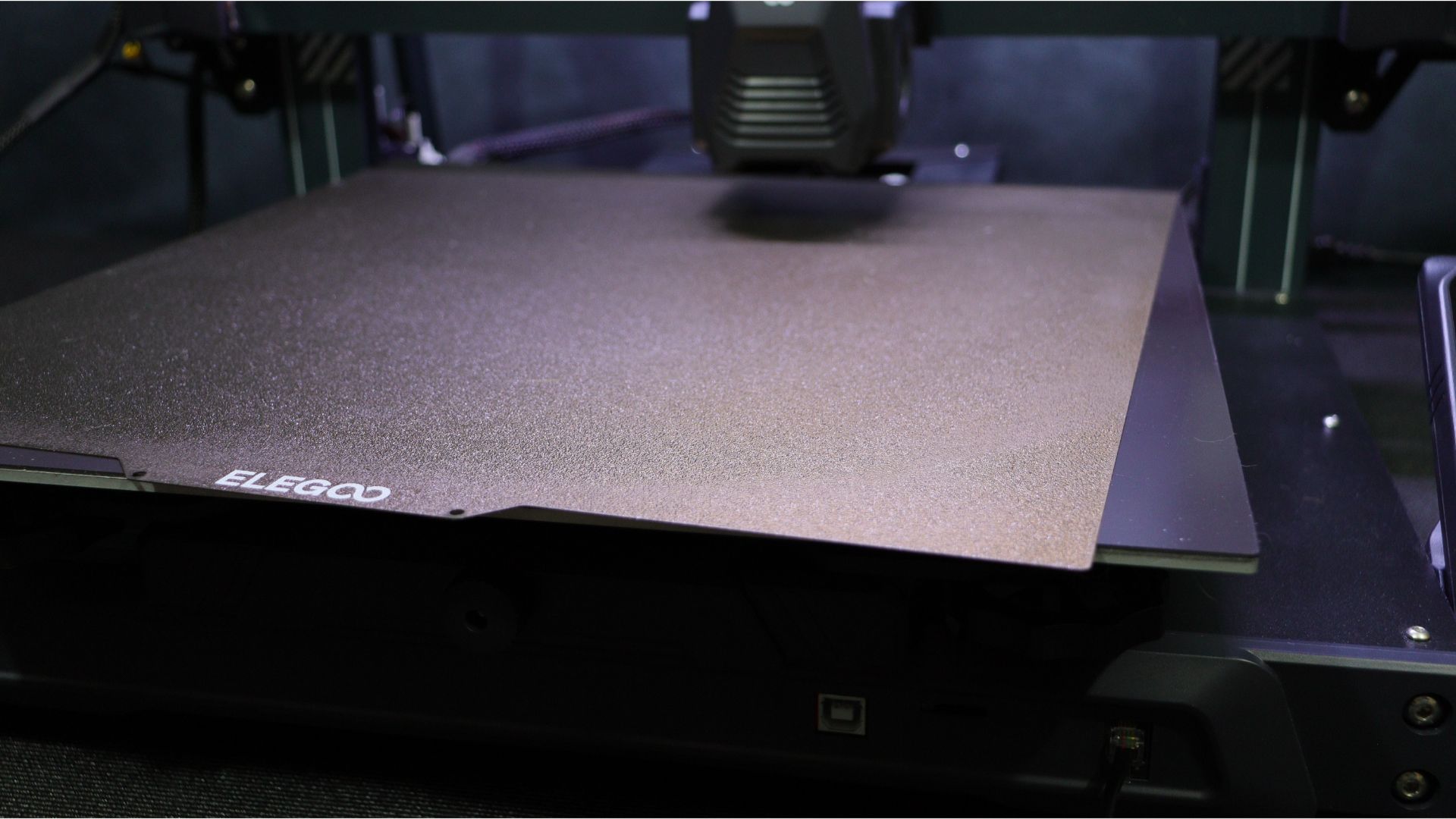

The Neptune 3 Plus shares the same direct drive configuration and 4.3-inch touchscreen as the Pro and Max as well as the X and Y axis belt tension adjustment knobs. In addition to the textured magnetic spring steel PEI sheet, which leaves a textured surface on the bottom of the prints, the smooth side can be used to print but may require some adhesion assistance but will leave a smooth, glass-like finish on the bottom if that's what's needed.

Levelling: 49-point Automatic Mesh leveling

Build Volume: 320x 320 x 400mm

Printer Dimensions: 533 x 517 x 638mm

Printing Speed: 30-180mm/s

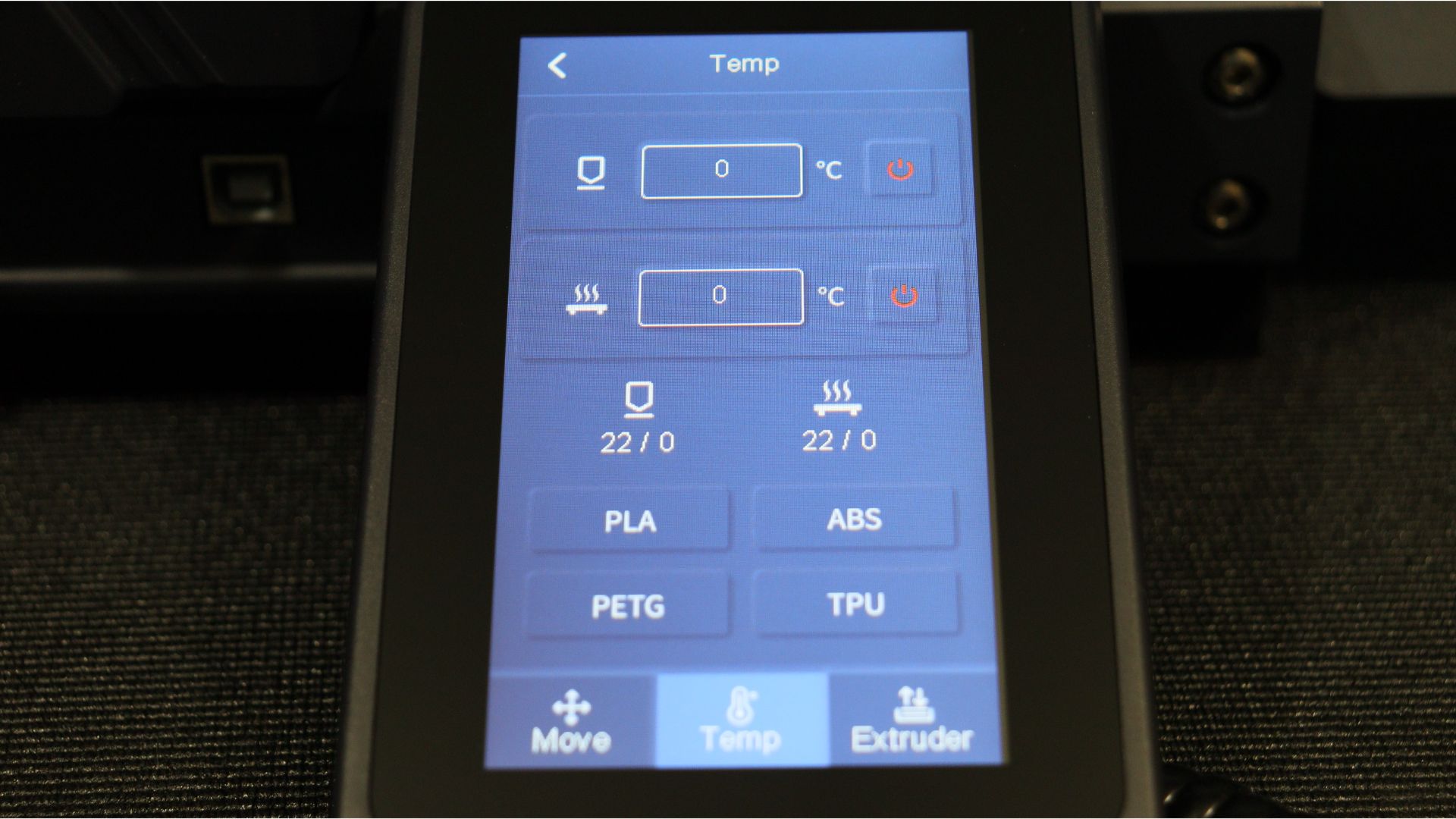

Nozzle Temperature: 260°C / 500F

Hot Bed Temperature: 100°C / 212F

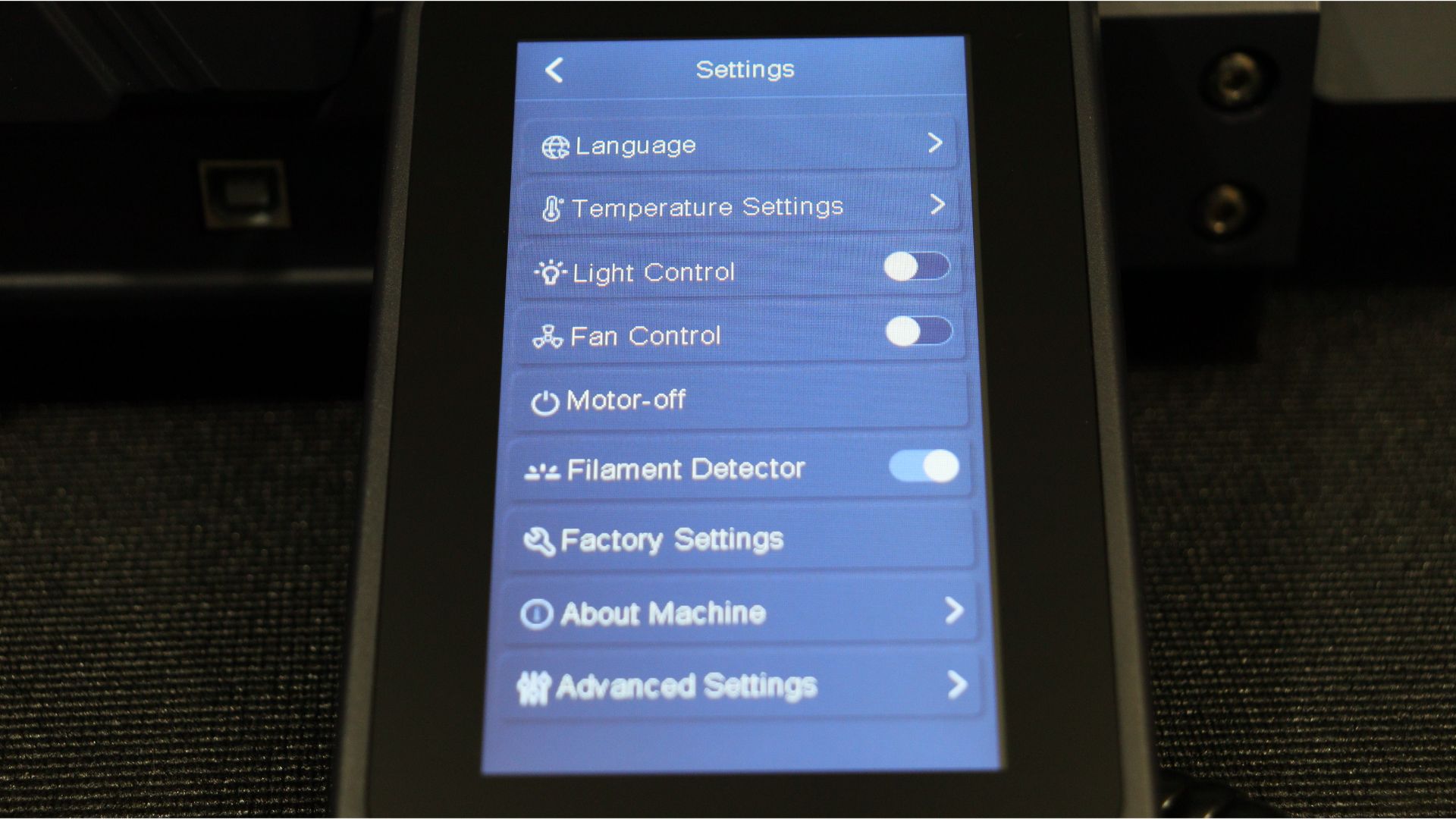

Control panel: 4.3-inch color touchscreen LCD

Platform: Magnetic Flexible PEI sheet

Supported filaments: PLA, ABS, TPU, PETG, WOOD, etc

Net weight: 31.3 lbs / 14.2KG

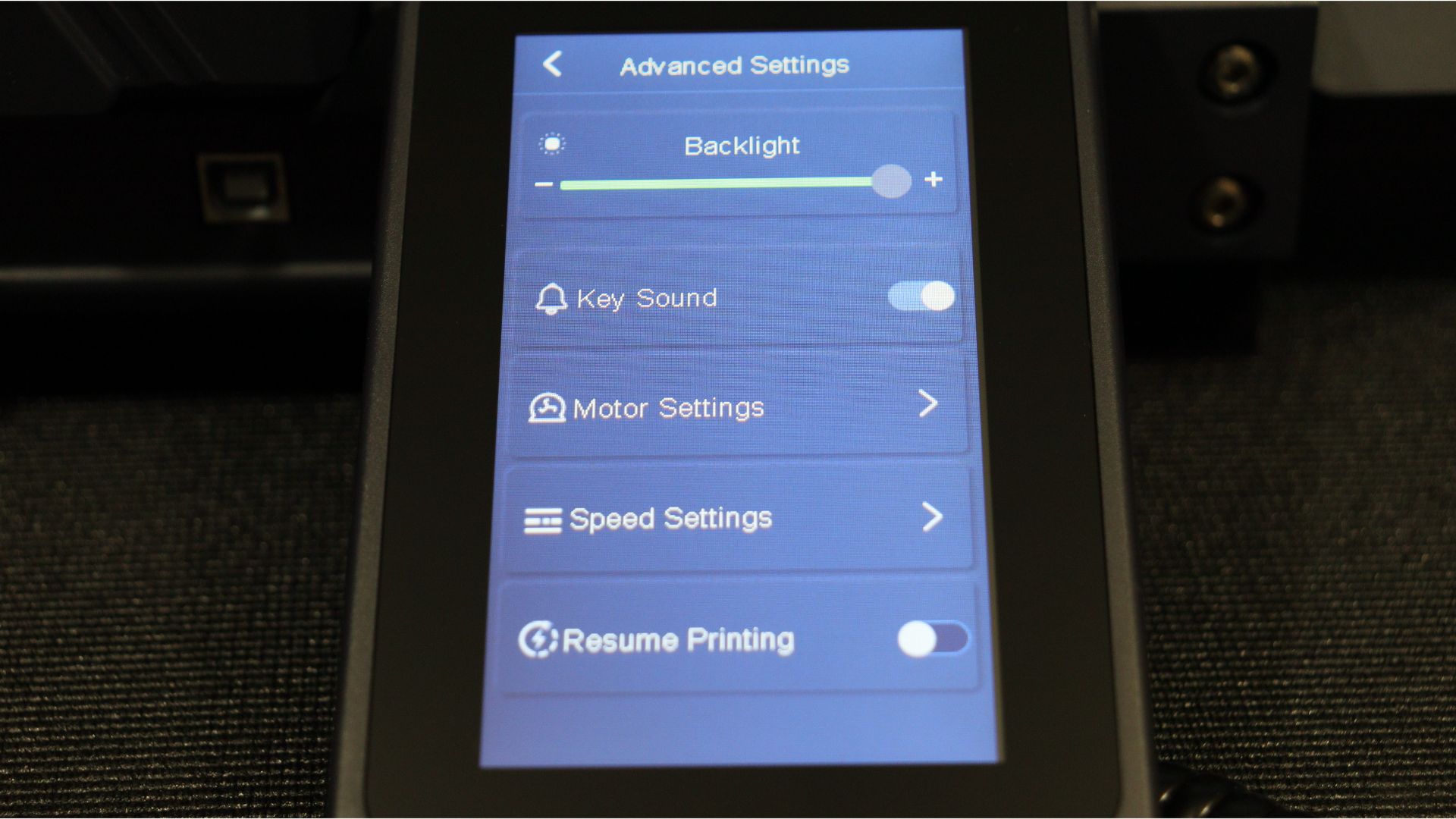

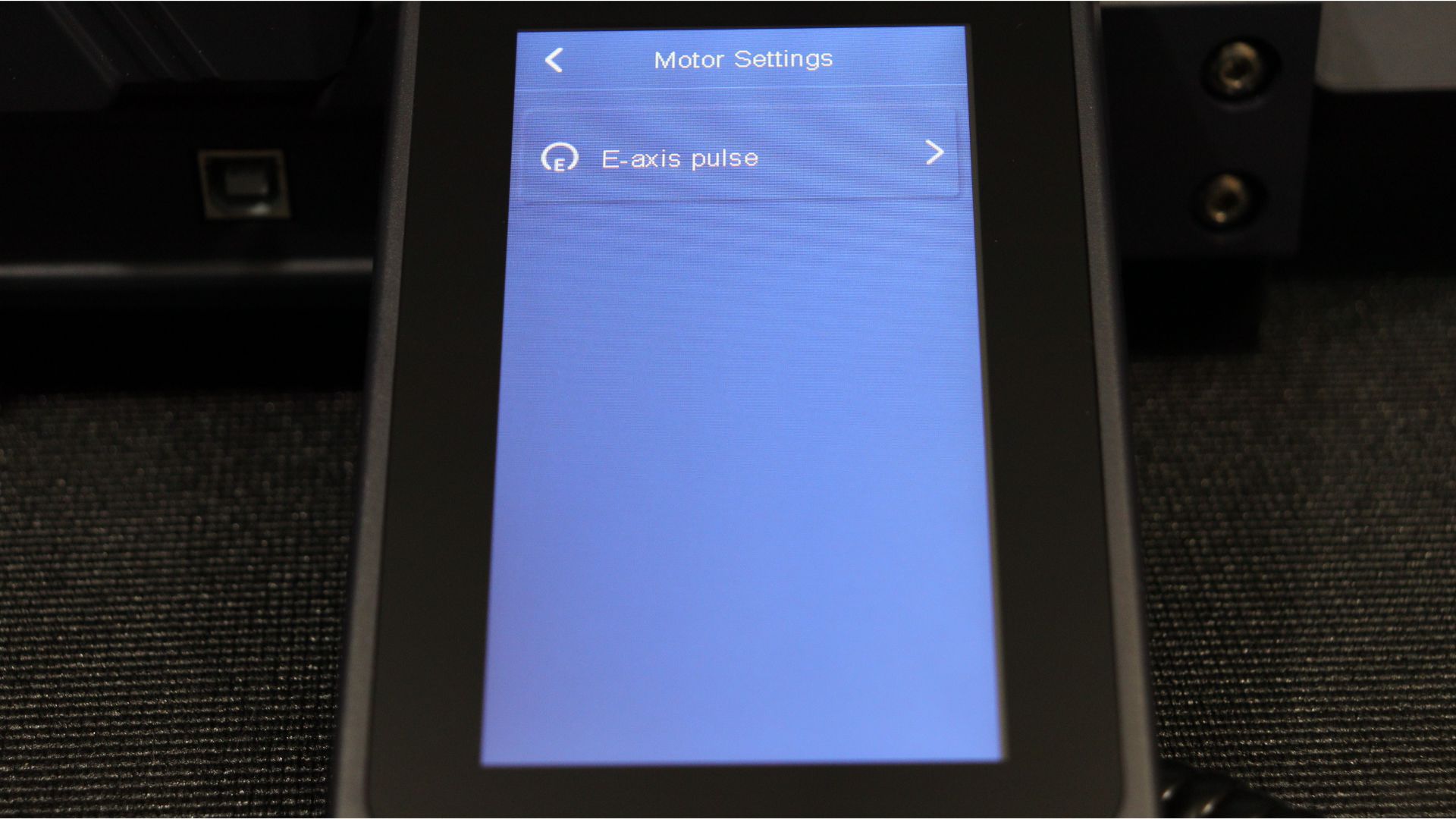

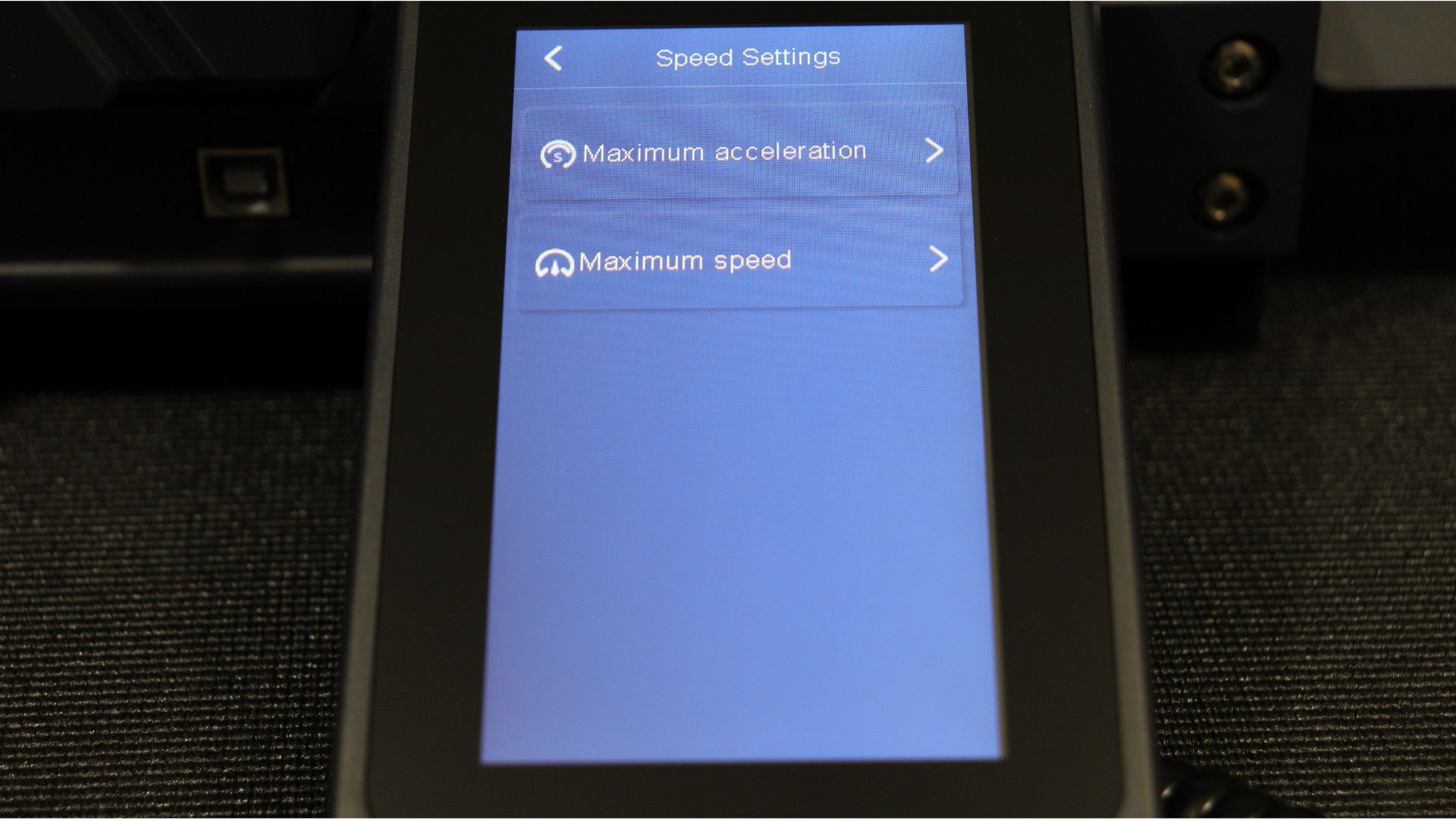

The Neptune 3 Plus contains all the features required for fine-tuning the printer, including the manual and auto-level menus as well as configuration options for changing your printer's settings as well as acceleration and jerk, making it simple to make adjustments. A coiled cord that connects the LCD to the printer and enables screen removal makes it much simpler to change options and load prints thanks to the magnetic cradle.

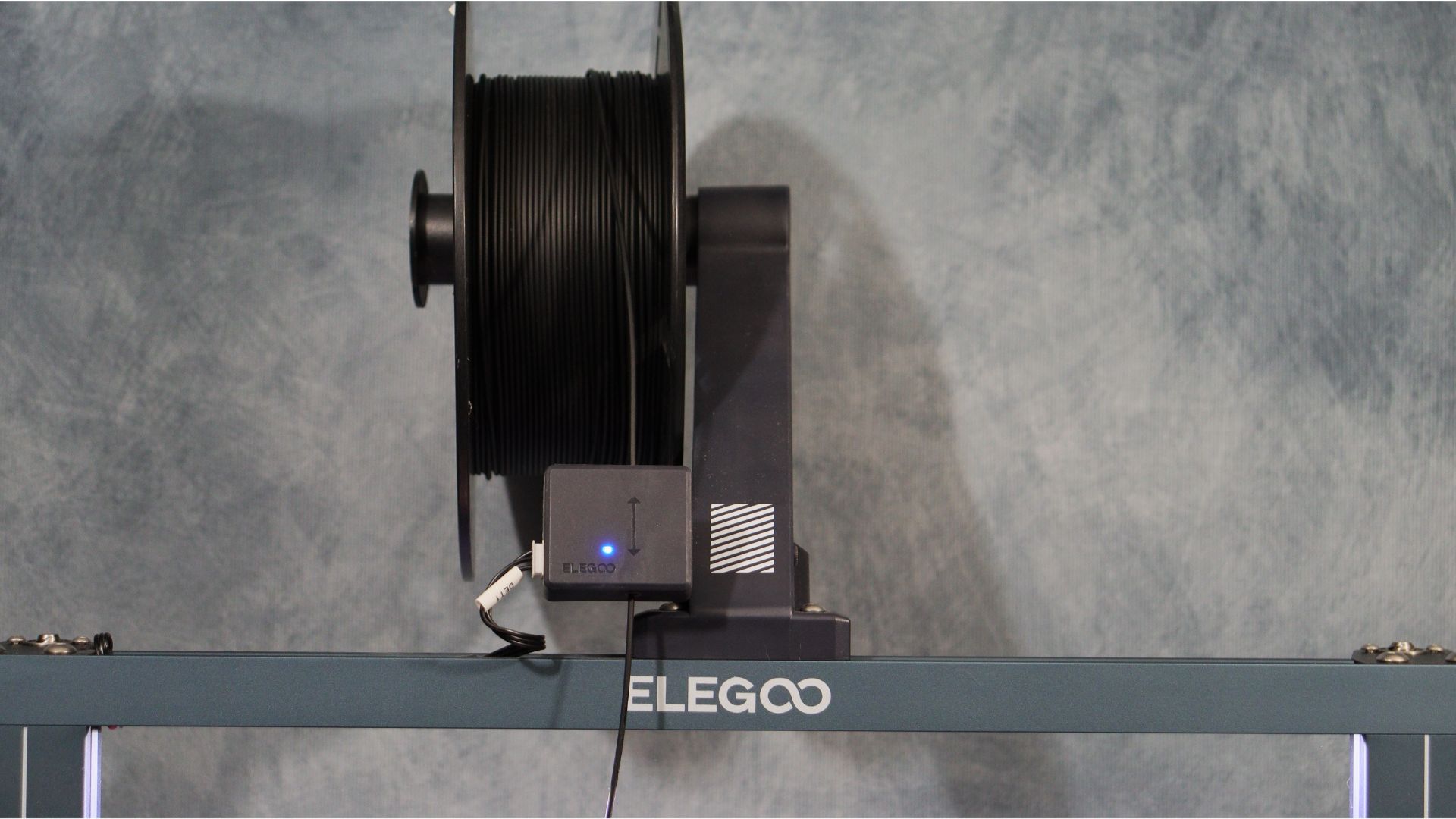

Finally, the spool holder is top mounted and robustly built - we've seen a lot of flimsy plastic spool holders on other printers in this price range and we're glad that Elegoo hasn't gone down that route here.

Elegoo Neptune 3 Plus: Print quality & speed

The included test print with Polymaker polylite PLA was the first print we produced on the Neptune 3. There were no obvious problems with the print and neither over-extrusion nor under-extrusion could be seen.

We decided to attempt a couple more small test prints before we moved onto fancier designs. The typical 3D Benchy boat comes first. Utilizing the default profile included with the Elegoo Cura, we printed the benchy at a speed of 80 mm/s. It worked out well; there were no problems, not even on the roof of the boat's overhangs or bridges. By tightening the X-axis belt, the we managed to eliminate the typical ghosting issue on the front of the hull.

For the final small test print, we selected the well-known Cali-Dragon model from Cults 3D, which is a perfect test for overhangs, ghosting on both axes, and stringing issues between the horns. The dragon printed flawlessly using the same settings; there is no stringing between the horns and the backs of the horns are clean.

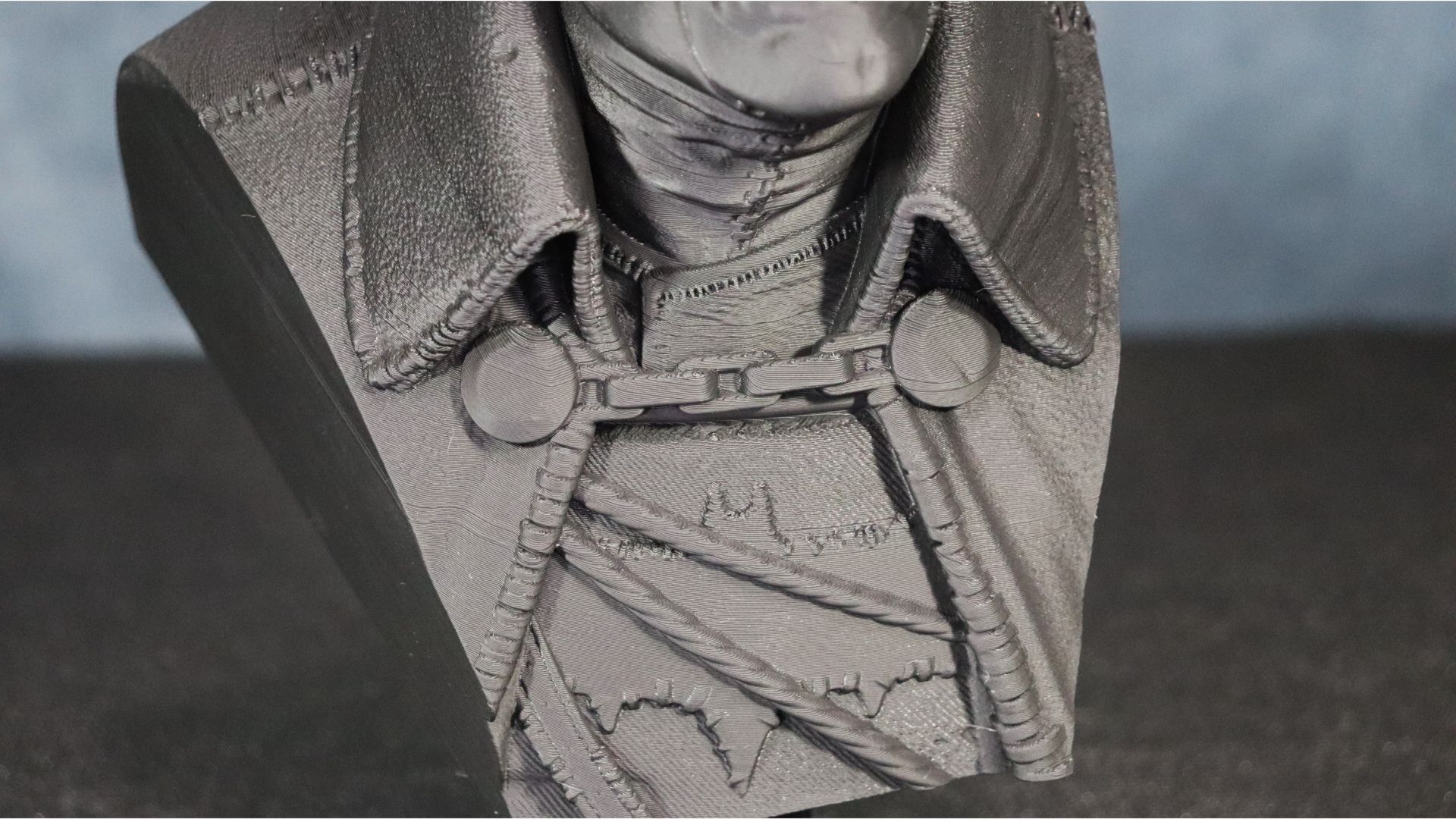

We chose to try a more intricate model after the initial tiny test prints came out well. This Batman Gaslight V2 bust by Eastman was printed at an 80mm/s with 0.2mm layer height. The bust turned out fantastic; the fabric of the garment and the armor both have incredible detail. There were no problems with the finished product. The twin part cooling fans prevent any sagging of the overhang on the nose of the cowl.

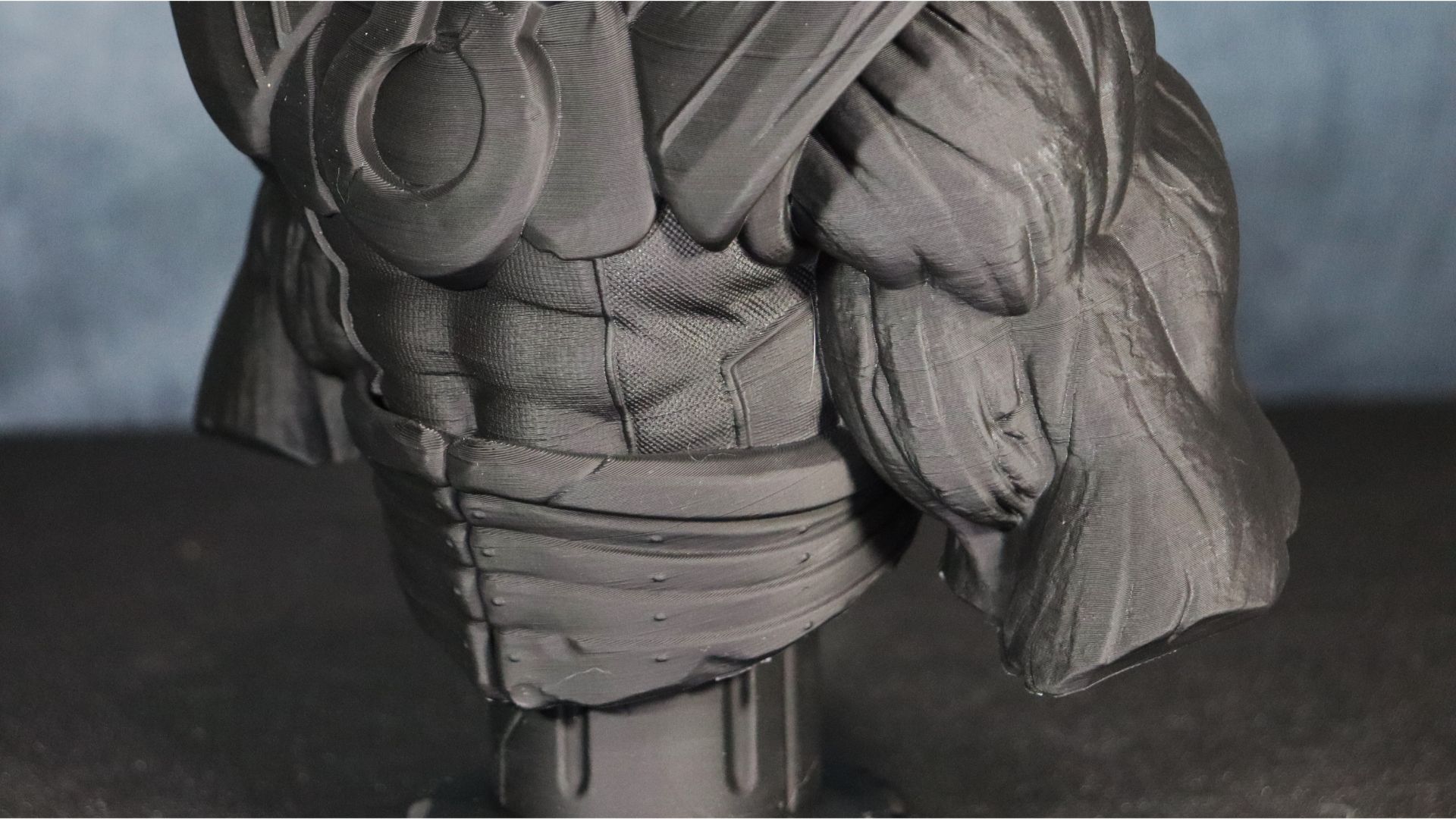

We sliced and printed the Darkseid bust from Eastman after the Batman bust's success. The identical settings produced the same outcomes as prior prints: everything was clean, there were no problems, and the remarkable detail on the fabric and texture of Darkseid's arms could be seen. This might even effectively compete with resin printers if it were printed at a lower layer height.

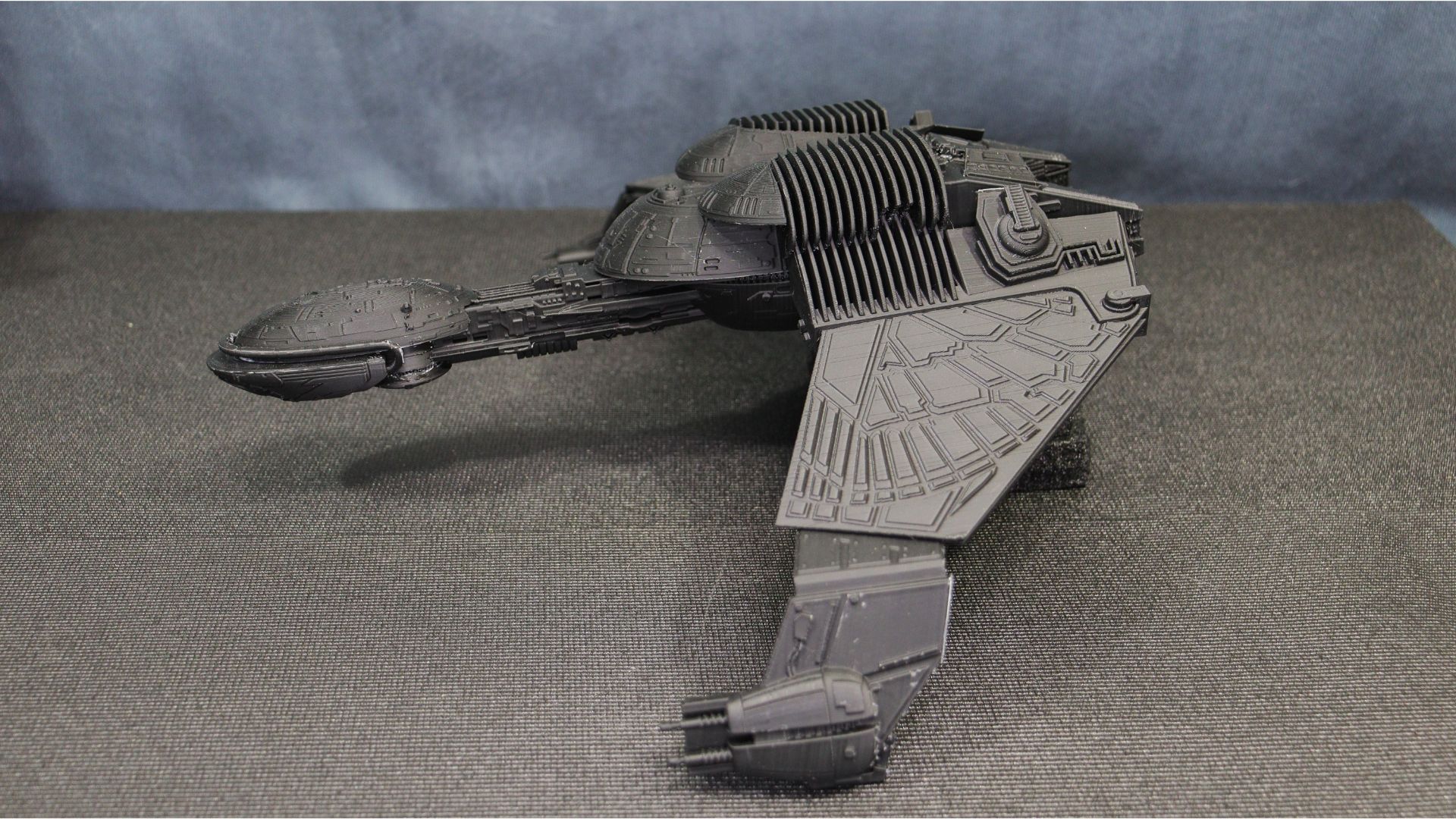

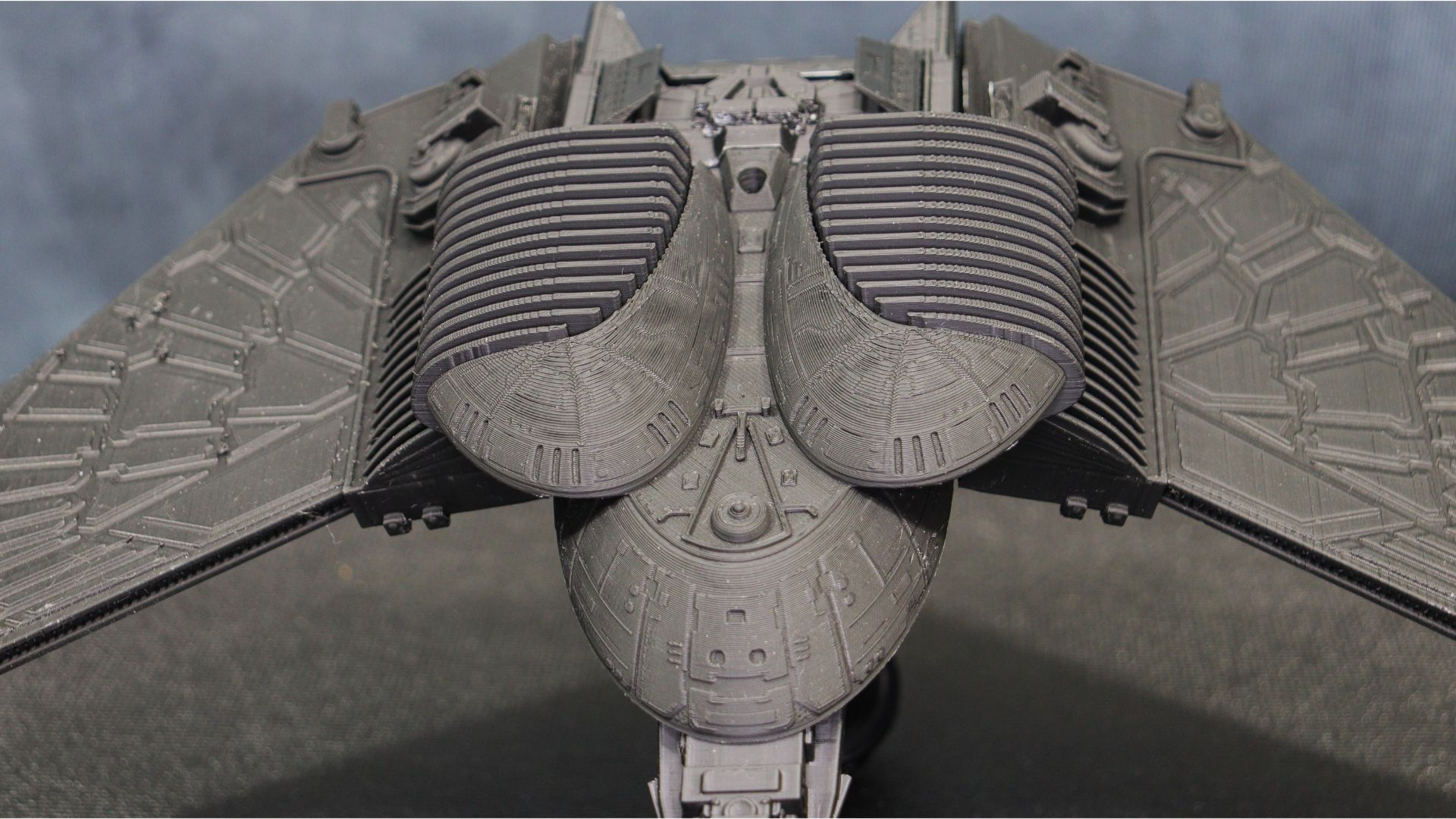

We then decided to try something a little more intricate with a few more parts for the final print. Gambody's Klingon Bird of Prey is shown here; it is printed in several pieces, and gears are included to allow the wings to move from the normal to landing position. This print made good use of the build volume because we could fill the bed with parts, and, as with earlier prints, we used the same slicer settings with the exception of a few minor support settings adjustments.

To complete all the elements required to assemble the ship, it took around a day and a half to print. With models like this, printer accuracy is essential to ensure correct fit and functionality. A few issues caused by support settings were the only issues with the printed pieces, and they were readily addressed.

The outcome is fantastic. Even at 0.2mm layer height, the detail is excellent, the pieces are simple to assemble, and the internal gears that move the wings work freely and without binding. One of the more impressive FDM printers we have examined this year the Neptune 3 Plus, which is poised to land among the top ranks on our list of the best 3D printers.

Should you buy the Elegoo Neptune 3 Plus?

With a $350 price tag and a build volume of 320x320x400mm, the Elegoo Neptune 3 Plus is one of the most promising 3D printers in the price range. In addition to having a full feature printer with direct drive and auto levelling, the Neptune 3 Plus also has an easy-to-use touchscreen with all the tools needed to calibrate and fine-tune the printer.

Comparable printers in the same price range are in the 220x220x250mm or 235x235x250mm build volume range. You cant beat the value included with the Neptune 3 Plus.

If this product isn't for you?

If you need something a little bigger than the Plus, the Elegoo Neptune 3 Max might be thw way to go. It has a hefty build capacity of 420x420x500mm, and with an MSRP of $470, it won't break the bank either.

If size is not a concern, the Elegoo Neptune 3 Pro is available for $230 USD. Elegoo looks to have the printer that will meet your needs, no matter what your needs or budget are.

Will is a freelance writer from Canada and 3D printing guru. If you need to know anything about 3D printing, slicing software, or 3d modelling, he's your guy. As a result, you'll find him reviewing the latest 3d printers for Space.com, as well as offering handy tips and buying advice for newcomers to the field.