Boeing's New Crew-Carrying Spaceship Taking Shape

CLEAR LAKE, Texas — Boeing’s new private spaceship may be ready to carry astronauts to the International Space Station and other locales in low-Earth orbit by 2015, company officials say.

Work on CST-100 design, manufacture, testing and evaluation is well underway. So too is scoping out launch vehicle and mission operations to support NASA’s commercial crew development program, which aims to spur the astronaut-carrying capabilities of private spacecraft.

For example, Boeing successfully completed a helicopter-aided parachute drop test of the craft Tuesday (April 3) at the Delamar Dry Lake Bed near Alamo, Nev. Three main parachutes deployed to slow the capsule’s descent before six airbags inflated as part of the ground landing system. This first appraisal of the fully combined CST-100 landing system will be followed by another test later this month.

Nevada-based company Bigelow Aerospace, a Boeing partner that is developing large, expandable space habitats, played a key role in the drop test.

Company founder and president Robert Bigelow noted in a press statement: "If astronauts had been in the capsule during these drop tests, they would have enjoyed a safe, smooth ride… further proof that the commercial crew initiative represents the most expeditious, safest, and affordable means of getting America flying in space again." [Photos of the CST-100]

Pulling in proven technology

Significant progress is being made toward flying a first crewed CST-100 mission atop an Atlas 5 rocket in 2015 or 2016, said John Mulholland, vice president and program manager for Boeing Commercial Programs.

Breaking space news, the latest updates on rocket launches, skywatching events and more!

The CST-100 is drawing upon flight-proven hardware, Mulholland told SPACE.com here. "When you’re in a fixed-price development, you want to use mature designs. You cannot have technology development on a critical path."

Pulling in proven technology, Mulholland said, includes utilizing Apollo-era heat shield and space shuttle thermal protection technology, as well as autonomous rendezvous and docking gear honed on the Pentagon's experimental satellite-refueling Orbital Express mission.

The CST-100 also adopts flight computers in use on the military’s secretive, Boeing-built X-37 space plane, he added.

Price point

The CST-100 capsule measures 14.8 feet (4.5 meters) across at its widest point. It can hold up to seven astronauts, or some combination of crew and cargo. The spacecraft is certified to stay in low-Earth orbit for six months, and each capsule will be able to fly 10 times, Mulholland said.

"When you look at commercial crew…and trying to get the price point, something low enough in cost to have a sustainable market, the capsule was a clear winner," Mulholland added.

Initial flights of the CST-100 are to be boosted by an Atlas 5.

As other launch providers, such as SpaceX and ATK’s Liberty Transportation System, demonstrate performance and reliability for crew transport, Boeing is maintaining the option of competition for launch vehicle procurement, Mulholland said. "So we’re keeping our design compatible with multiple launch vehicles." [Vote Now! The Best Spaceships of All Time]

CST-100 sports a four-engine "pusher abort system" rather than an escape tower as used in the Mercury and Apollo programs. The capsule is designed to land on terra firma, but also can support a water landing in case of an abort.

Mission control

Boeing has scheduled additional tests to be performed later this year, including a landing airbag test series in May, a forward heat shield jettison test in June, and an orbital maneuvering/attitude control engine hot fire test in June. All will help engineers gather more data on key aspects of the CST-100 design.

Last October, Boeing announced plans to consolidate its Commercial Crew program office, manufacturing and operations at NASA's Kennedy Space Center in Florida. Boeing, in partnership with Space Florida, has an arrangement to use KSC's Orbiter Processing Facility-3 to manufacture, assemble, and test the company’s CST-100 spacecraft.

Mulholland also pointed out that a NASA Space Act Agreement has been signed with the Johnson Space Center in Houston for operating flight of the CST-100. A spacecraft operations center in Florida is also planned, first in a support role, but later to take over mission control duties, he said.

To date, NASA has provided Boeing with about $120 million for its commercial crew transportation work. On the aerospace firm’s side, Boeing has invested "a significant amount," Mulholland said, declining to give an exact number.

Large, leasable habitats

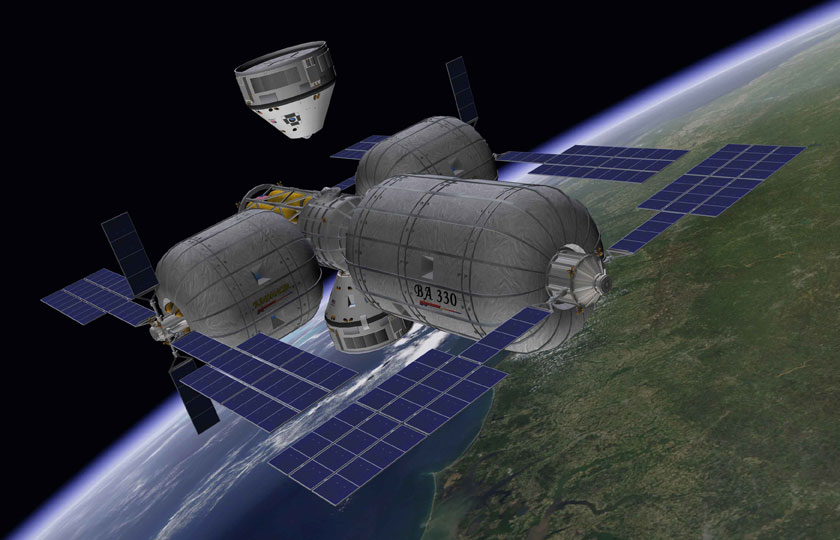

Boeing is also partnering with Bigelow Aerospace of North Las Vegas, Nev., which is developing large and leasable expandable space habitats.

"[Robert Bigelow[ has been a great partner and provided us a lot of value," Mulholland said. "They are about to sign a contract with the International Space Station to put an inflatable module up there. Getting that NASA seal of approval will really help stimulate the market."

Additionally, Boeing is partnered with space tourism provider Space Adventures. Space Adventures intends to sell unused seats on the CST-100 for flights to low-Earth orbit.

Casting an eye toward the business case for commercial space, Mulholland said he expects markets to materialize. "My team and I are focused on getting the vehicle ready. We’ve got good partners and we hope to build a service."

Mulholland said he has no doubt that markets are going to emerge, but he does wonder about the pace. In cranking out capsules, he said, the company has a low, a medium and a high business model.

"The market is obviously going to be there," Mulholland said. "I hope it’s in the near-term…but I’d say right now, it is soft because no one has been able to penetrate and really do it on a recurring basis. We’ll see."

Leonard David has been reporting on the space industry for more than five decades. He is a winner of last year's National Space Club Press Award and a past editor-in-chief of the National Space Society's Ad Astra and Space World magazines. He has written for SPACE.com since 1999.

Follow SPACE.com for the latest in space science and exploration news on Twitter @Spacedotcom and on Facebook.

Leonard David is an award-winning space journalist who has been reporting on space activities for more than 50 years. Currently writing as Space.com's Space Insider Columnist among his other projects, Leonard has authored numerous books on space exploration, Mars missions and more, with his latest being "Moon Rush: The New Space Race" published in 2019 by National Geographic. He also wrote "Mars: Our Future on the Red Planet" released in 2016 by National Geographic. Leonard has served as a correspondent for SpaceNews, Scientific American and Aerospace America for the AIAA. He has received many awards, including the first Ordway Award for Sustained Excellence in Spaceflight History in 2015 at the AAS Wernher von Braun Memorial Symposium. You can find out Leonard's latest project at his website and on Twitter.