3D Printing Photos: Europe's Project AMAZE for Space Travel

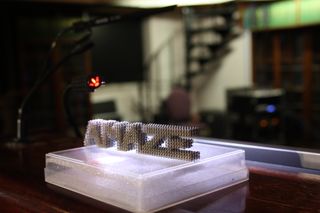

3D Printed AMAZE Logo

Pieces like the example in this photo were shown in the London Science Museum, UK, on Oct. 15 where international experts presented the world’s largest metal 3D-printing project, lead by ESA and the EU. AMAZE – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. 3D printing builds a solid object from a series of layers, each one printed on top of the last. This ‘additive manufacturing’ technique produces very complex structures with minimal waste and maximum flexibility. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

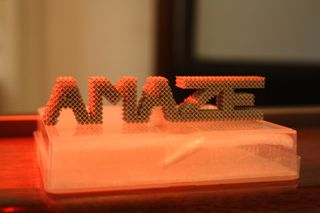

3D Printed Item at ESA’s AMAZE Press Event

Pieces like the example in this photo were shown in the London Science Museum, UK, on Oct. 15 where international experts presented the world’s largest metal 3D-printing project, lead by ESA and the EU. AMAZE – Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. 3D printing builds a solid object from a series of layers, each one printed on top of the last. This ‘additive manufacturing’ technique produces very complex structures with minimal waste and maximum flexibility. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

3D Printed AMAZE Program Logo

Pieces like the example in this photo were shown in the London Science Museum, UK, on Oct. 15 where international experts presented the world’s largest metal 3D-printing project, lead by ESA and the EU. AMAZE – Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. 3D printing builds a solid object from a series of layers, each one printed on top of the last. This ‘additive manufacturing’ technique produces very complex structures with minimal waste and maximum flexibility. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

3D Printing Project Participant Amazed at Press Event

ESA and the European Commission have embarked on a project to perfect the printing of space-quality metal components. The AMAZE project – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

3D-Printed Pieces on Display at AMAZE Conference

3D printing builds a solid object from a series of layers, each one printed on top of the last. This ‘additive manufacturing’ technique produces very complex structures with minimal waste and maximum flexibility. Pieces like the examples in this photo were shown in the London Science Museum, UK, on Oct. 15 where international experts presented the world’s largest metal 3D-printing project, lead by ESA and the EU. AMAZE – Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

AMAZE Participant Eyes 3D-Printed Piece

A participant observes a 3D printed metallic object at a press conference at the London Science Museum, UK, Oct. 15 where an international panel of experts presented the world’s largest metal 3D printing project lead by ESA and the European Union. The AMAZE project – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

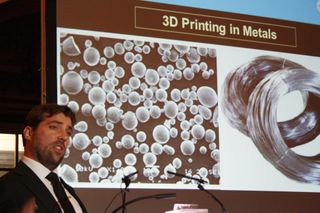

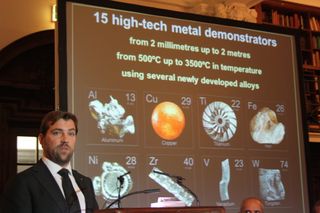

ESA’s David Jarvis at AMAZE 3D Printing Project Press Conference

David Jarvis, ESA’s Head of New Materials and Energy Research, at a press conference at the London Science Museum, UK, on Oct. 15. The AMAZE project – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

Get the Space.com Newsletter

Breaking space news, the latest updates on rocket launches, skywatching events and more!

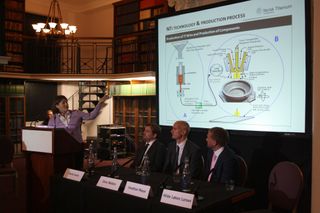

AMAZE Expert Panel Addresses Participants

International experts presented the world’s largest metal 3D-printing project at the London Science Museum, UK, on Oct. 15. AMAZE – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

ESA’s David Jarvis Speaks at AMAZE Press Conference

David Jarvis, ESA’s Head of New Materials and Energy Research, at a press conference at the London Science Museum, UK, on Oct. 15. The AMAZE project – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

3D Printing Expert Speaks at AMAZE Press Conference

Hilde Loken Larsen, Head of Research and Development Activities, Norsk Titanium AS, addresses attendees at a press conference at the London Science Museum, UK, on Oct. 15. The AMAZE project – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

AMAZE Expert Panel Speaks at Press Conference

International experts presented the world’s largest metal 3D-printing project at the London Science Museum, UK, on Oct. 15. AMAZE – Additive Manufacturing Aiming Towards Zero Waste and Efficient Production of High-Tech Metal Products – involves 28 industrial partners across Europe. [Read the Full Story of ESA's AMAZE 3D Printing Project here.]

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: community@space.com.

Space.com is the premier source of space exploration, innovation and astronomy news, chronicling (and celebrating) humanity's ongoing expansion across the final frontier. Originally founded in 1999, Space.com is, and always has been, the passion of writers and editors who are space fans and also trained journalists. Our current news team consists of Editor-in-Chief Tariq Malik; Editor Hanneke Weitering, Senior Space Writer Mike Wall; Senior Writer Meghan Bartels; Senior Writer Chelsea Gohd, Senior Writer Tereza Pultarova and Staff Writer Alexander Cox, focusing on e-commerce. Senior Producer Steve Spaleta oversees our space videos, with Diana Whitcroft as our Social Media Editor.